Case Study: FIT.technology as an agile development partner for rapid prototyping solutions

Project:

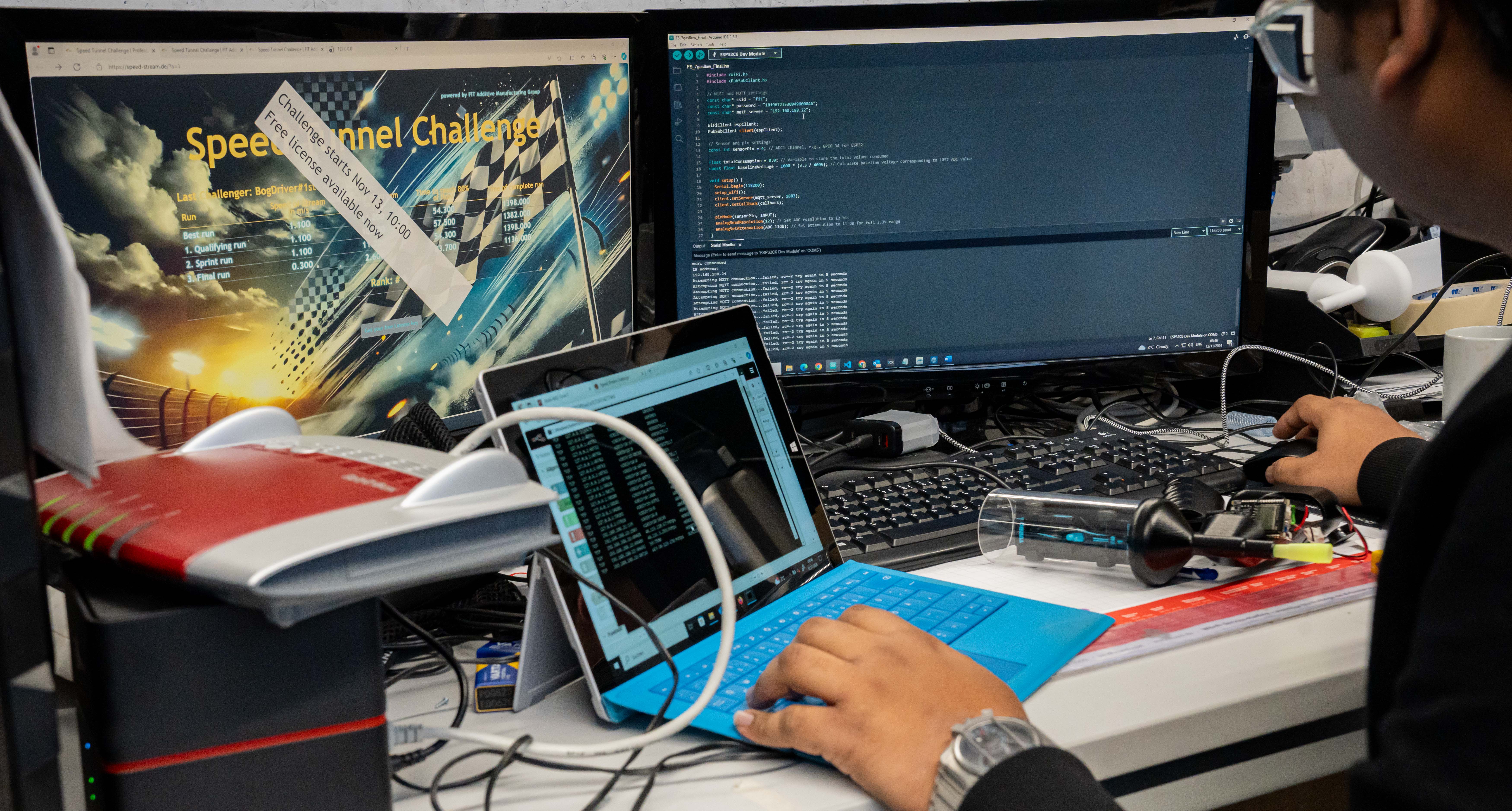

Speed Tunnel Challenge – a rapid concept implementation from idea to exhibition showcase

Challenge:

Within an extremely tight timeframe of just 11 business days, FIT.technology was tasked with transforming a basic idea from a hand sketch into a fully functional trade show prototype. This required quick reactions, flexible resource planning, and the integration of multiple technologies to meet quality and functionality requirements.

Solution approach and technologies:

To meet this challenge, FIT.technology employed an agile, iterative development process, executing parallel tasks across multiple domains. The project team consisted of a project manager and three key developers responsible for CAD design, electronics, and web integration. The involved technologies included:

- SLS (selective laser sintering) for precise and robust part production

- chemical smoothing and dyeing for esthetic and functional surface optimization

- laser cutting and sheet metal bending for mechanical components

Procurement and manufacturing processes:

Due to the tight timeframe, procurement processes had to be accelerated through special approvals, allowing purchases from outside the approved supplier network. This ensured that necessary materials were available on time.

Development and iterations:

A critical factor in the project’s success was the iterative refinement of the gun unit. The gun underwent five rounds of iterations, with two prototypes produced in each round, gradually refining functionality to meet the evolving requirements. Only the final version was chemically smoothed and dyed in order to achieve the desired esthetics and functionality while ensuring efficient resource use.

Final product:

The “Point of Game” (POG) unit was designed as a robust stainless steel stand, integrating a display with a secure gun holder. The total budget amounted to approximately €15,000, coming in below the originally agreed maximum budget of €20,000. Producing additional POG units would incur a per-unit cost of around €3,500.

Milestone-driven approach:

The project milestones were strictly adhered to, serving as a framework for both budget and timeline. The electronics prototype was ready after 5 business days, and the MVP (Minimum Viable Product) of the gun unit was completed by day 7. Regular milestone checks allowed for efficient project management, keeping the project on track and within budget.

Pilot deployment and further development:

Following the initial deployment at the Professional MotorSport World Expo 2024, all feedback collected at the event will be used to define additional practical requirements for the final version. This step ensures that specific optimizations and adjustments can be made, tailoring the POG unit to be even more effective and user-friendly for future events. The feedback-driven development phase allows for precise alignment of the final product with real-world needs and user expectations.

Outcome and key insights:

The successful implementation of the Speed Tunnel Challenge project within such a tight timeframe demonstrates FIT.technology’s ability to deliver fast and high-quality development solutions for complex requirements. The project showcases the need for flexibility, precision, and innovation in development support, manufacturing, and project management. Clients requiring rapid, reliable prototyping or product development will find in FIT.technology a reliable partner capable of delivering impressive results through targeted iteration and efficient resource use.

Summary:

This project illustrates that even under tight budgets and timelines, successful outcomes are achievable by combining agile methods, a clear milestone plan, and the application of state-of-the-art manufacturing technologies. FIT.technology’s agile approach offers clients not only a rapid initial version but also continuous optimization based on real user feedback – a real competitive advantage when developing innovative product solutions.