Konventionelle Verfahren

Wir sind DER Spezialist für Additive Fertigung. Das heißt aber auch, dass wir genau wissen, dass 3D-Druck nicht die einzige Antwort für jedes Anliegen ist. Manchmal kann es viel wirtschaftlicher sein, Teile eines Produkts konventionell zu fertigen. Oder die Stärken der Additiven Fertigung nicht für die Teilefertigung, sondern für die Werkzeugherstellung zu nutzen.

Daher halten wir auch einen umfassenden Katalog an konventionellen Herstellungstechniken für Sie parat, so dass wir in jedem Fall die in punkto Kosten und Qualität beste Lösung anbieten können.

- Spritzguss

- Elastomerfertigung

- Vakuumguss

- NEU: Formschäumen Mold One Flex

- Polyamidguss

- Feinguss

- Reaction Injection Molding (RIM)

- CNC-Fräsen

- Laminieren

Spritzguss

Verfahrensbeschreibung

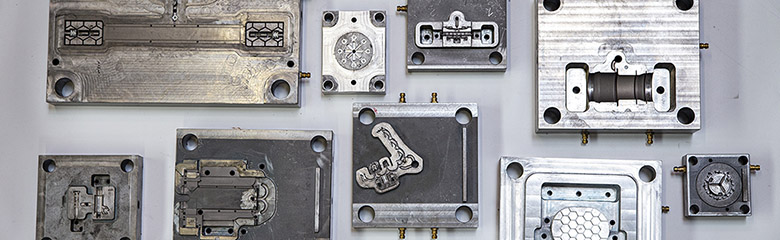

Beim Spritzguss wird ein Kunststoffgranulat in einer Spritzeinheit plastifiziert, d.h. erwärmt und aufgeschmolzen. Anschließend wird der flüssige Kunststoff unter hohem Druck in den Hohlraum (Kavität) des Werkzeugs eingespritzt, wobei die Kavität Form und Oberflächenstruktur des Bauteils bestimmt. Nach dem Erstarren des Materials wird das Bauteil aus dem Werkzeug entnommen. Beim Spritzguss lassen sich Hinterschnitte durch Losteile und Schieber realisieren. Auch das Umspritzen von Einlegern (Insert- oder Outserttechnik) ist möglich. Die Werkzeuge werden je nach Kundenanforderung auf Ausbringmengen von ca. 1.000-50.000 Stück angelegt. Das Besondere bei FIT ist die Werkzeugfertigung, denn die Werkzeuge werden additiv mittels Laserschmelzen (LM bzw. PBF-LB/M) aus Aluminium oder Stahl bereits innerhalb weniger Tage hergestellt. Das trägt dazu bei, die Lieferzeiten von Spritzgussteilen erheblich zu verkürzen.

Kostengünstige Serienteile

Mit Spritzguss lassen sich kleine Losgrößen mit serienidentischen Eigenschaften günstig und schnell realisieren. Die Bauteile können direkt für Testzwecke oder die Endanwendung verwendet werden. Dazu werden nahezu beliebige thermoplastische Elastomere oder technische Kunststoffe monochrom oder in Farbe verarbeitet. Da die gesamte Fertigung von der Werkzeugkonstruktion über die Werkzeugherstellung bis zum Spritzguss direkt bei FIT erfolgt, können die ersten Bauteile bereits innerhalb weniger Arbeitstage geliefert werden. Spritzguss eignet sich ideal z.B. für:

- Prüfung der Optik oder der Serienreife des Designs

- Validierung der Bauteilfunktion

- Materialtests

- Vorserien, falls das Serienwerkzeug auf sich warten lässt oder die Losgröße noch unklar ist

- Kleinserien von Bauteilen mit niedrigen Losgrößen

Angebot einholen >

Ansprechpartner kontaktieren >

Elastomerfertigung

Verfahrensbeschreibung

Elastomerteile können mittels IM-Verfahren (Injection Molding) oder im CM-Verfahren (Compression Molding) hergestellt werden. Beim IM-Verfahren wird eine plastifizierte Gummimischung in ein beheiztes Formwerkzeug gespritzt und danach vulkanisiert. Für das CM-Verfahren wird eine Vulkanisationspresse verwendet, welche die Formteile mittels Presswerkzeugen in Form bringt. Auch hier werden die Bauteile anschließend vulkanisiert. Welches Werkzeug und welches Verfahren zum Einsatz kommen, ist abhängig von der Bauteilgeometrie und der Stückzahl. Je nach Werkzeug können Ausbringungsmengen von 1.000 bis 100.000 Stück erreicht werden. Neben der Fertigung von Formteilen aus Gummi können bei FIT auch Verbundteile produziert werden, indem Metall- und Kunststoffelemente wie Buchsen, Kontaktbleche, Gewindeeinsätze etc. umspritzt werden. Hierzu werden die Einlegeteile speziell vorbehandelt, um eine optimale Verbindung zwischen Einlegeteil und Elastomermaterial zu erreichen.

Flexible Fertigung

Mit Elastomerfertigung lassen sich robuste und (in der Regel) flexible Bauteile mit sehr guten mechanischen, chemischen und optischen Eigenschaften aus nahezu allen gängigen Elastomeren herstellen. Die Bauteile weisen dabei deutlich bessere Eigenschaften auf als additiv gefertigte, gummiähnliche Materialien. Da die gesamte Produktion von der Werkzeugkonstruktion über die Werkzeugherstellung bis zur Fertigung einschließlich der Nachbearbeitungsschritte Schleifen der Trennebenen, Touchieren und ggf. Polieren direkt bei FIT erfolgt, können die ersten Bauteile bereits innerhalb weniger Arbeitstage geliefert werden. Komplexere Pressformen können durch Additive Fertigung häufig effizienter und schneller als durch Fräsen hergestellt werden. Elastomerfertigung eignet sich ideal z.B. für:

- Gummi-Verschleißteile

- Validierung der Bauteilfunktion

- Materialtests

- Vorserien, falls das Serienwerkzeug auf sich warten lässt oder die Losgröße noch unklar ist

- Kleinserien von Bauteilen mit niedrigen Losgrößen

Angebot einholen >

Ansprechpartner kontaktieren >

Vakuumguss

Verfahrensbeschreibung

Basis für den Vakuumguss ist die Herstellung eines Urmodells, das im 3D-Druck mittels Stereolithographie (SLA) gefertigt wird. Das Urmodell wird nach der Festlegung von Formtrennung, Anguss und Steigern in einem Rahmen fixiert. Anschließend wird der Rahmen mit einem 2K-Silikon ausgegossen. Nach dem Aushärten des Silikons wird die Silikonform entlang der festgelegten Formtrennung mit einem Skalpell aufgeschnitten und das Urmodell wird entnommen. In diese leere Silikonform wird in einer Vakuumgießmaschine ein mehrkomponentiges PU-Harz (Polyol + Isocyanat) unter Vakuum gefüllt, um Lufteinschlüsse zu vermeiden. Nach dem Gießen kommt die Form zum Aushärten in einen Ofen. Die so erzeugten Teile werden nach einer materialabhängigen Entformzeit aus der Form entnommen und gefinisht. Anschließend steht die Form für weitere Abgüsse zur Verfügung. Die Ausbringmenge ist abhängig von der Bauteilgeometrie sowie dem Abgussmaterial und liegt auftragsabhängig für Prototypen und Klein- und Sonderserien zwischen 15 und 500 Teilen je Form.

Kleine Mengen in Spitzenqualität

Mit Vakuumguss lassen sich detailgetreue Bauteile aus einer großen Vielzahl an PU-Harzen fertigen. Die Bauteile weisen dabei Oberflächen auf, die in ihrer Qualität mit dem Spritzguss vergleichbar sind und sich sehr gut veredeln lassen. Damit ist der Vakuumguss eine schnelle, präzise und günstige Alternative zur Additiven Fertigung und zum Spritzguss. Vakuumguss eignet sich deshalb ideal z.B. für:

- Vor- und Kleinserien im Rahmen der Produktentwicklung

- Herstellung von Serienwerkzeugen

- Produktmuster

- Prototypen für Pass- und Funktionsprüfungen

- Design- und Messemodelle

- Ersatzteile oder Kleinserien für Endanwendungen, wie z.B. Verkleidungen, Abdeckungen, Gehäuse

- Lichtdurchlässige Behälter und transparente Displays

Anfrage schicken >

Ansprechpartner kontaktieren >

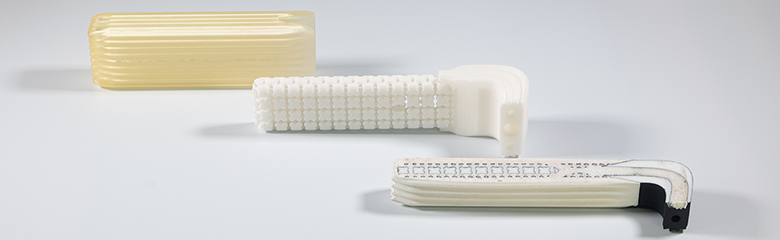

NEU: Formschäumen Mold One Flex

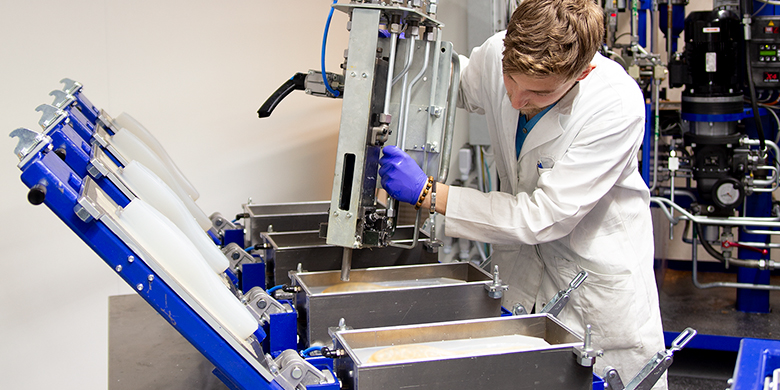

Verfahrensbeschreibung

Beim Formschäumen werden flüssige PU-Materialien wie Isocyanat und Polyol vermischt, die Reaktionsmasse schäumt in der Form der Hochdruckschäumanlage bei einem Druck von 0,8 bar auf. Im Anschluss härtet die Form samt Bauteil in einem Wärmeofen nach. Die Schaumdichte ist abhängig vom Mischverhältnis sehr gut steuerbar. Ein Standardwert ist beispielsweise 0,38 g/cm³.

Das Besondere am Hybridverfahren Mold One Flex ist die Kombination aus innovativen additiven und bewährten konventionellen Herstellmethoden. Für jedes Bauteil wird eine Einmal-Form im MSLA-Verfahren hergestellt. MSLA-Materialien haben den Vorteil, dass die Formen schnell, kostengünstig und mit hohen Kapazitäten sowie individualisiert hergestellt werden können und sich aufgrund der spröden Materialeigenschaften sehr einfach in einem Crush-Vorgang vom Bauteil entfernen lassen.

Alternative für Spritzguss

PU-Schäume haben eine hervorragende Dämm- und Dämpfwirkung und eignen sich deshalb ideal z.B. für:

- Individualisierte Massenprodukte wie Schuhsohlen

- Polster

- Dämmstoffe

- Stoßschutz für Verschleißteile

Anfrage schicken >

Ansprechpartner kontaktieren >

Polyamidguss (PA-Guss)

Verfahrensbeschreibung

Die Basis für den Polyamidguss ist, analog zum Vakuumguss, die Herstellung eines Urmodells, das im 3D-Druck mittels Stereolithographie (SLA) gefertigt wird. Das Urmodell wird nach der Festlegung von Formtrennung, Anguss und Steigern in einem Rahmen fixiert. Anschließend wird der Rahmen mit einem 2K-Silikon ausgegossen. Nach dem Aushärten des Silikons wird die Silikonform entlang der festgelegten Formtrennung mit einem Skalpell aufgeschnitten und das Urmodell wird entnommen. In einer Vakuumgießmaschine wird ein Monomer mit additiven und katalytischen Komponenten angereichert und zur Polymerisation unter Vakuum in die Silikonform gefüllt. Dadurch werden Lufteinschlüsse vermieden. Nach dem Gießen kommt die Form zum Aushärten in einen Ofen. Die so erzeugten Teile werden nach einer materialabhängigen Entformzeit aus der Form entnommen und gefinisht. Anschließend steht die Form für weitere Abgüsse zur Verfügung. Die Ausbringmenge ist abhängig von der Bauteilgeometrie sowie dem Abgussmaterial und liegt zwischen 10 und 15 Teilen je Form.

Seriennahe Kunststoffteile

Mit Polyamidguss lassen sich Kunststoffbauteile mit thermoplastischen Materialien (PA 6) herstellen, die über seriennahe Eigenschaften (Spritzguss) verfügen und im Vergleich zum Vakuumguss deutlich bessere chemische, thermische und mechanische Eigenschaften aufweisen. Auf Wunsch können die Bauteile nachbearbeitet, in nahezu jeder beliebigen Farbe lackiert oder mit Kupfer oder Nickel galvanisiert (Metal Coating) werden. PA-Guss eignet sich deshalb ideal z.B. für:

- Funktionsprototypen für Dauertests

- Komplexe Prototypen mit hoher Maßhaltigkeit (ca. +/- 0,3 %), wie z.B. Ansaugflansche, Führungen, Hebel oder Gehäuse

- Kleinserien oder Vorabserien, z.B. im Maschinenbau für Schiebeelemente, Spindelmuttern oder Kettenfließbänder

Angebot einholen >

Ansprechpartner kontaktieren >

Reaction Injection Molding (RIM)

Verfahrensbeschreibung

Reaction Injection Molding, auch bekannt als Niederdruck-Spritzgussverfahren, wird für die Herstellung von Kunststoffformteilen verwendet. Polyol und Isocyanat sowie mögliche weitere Zusätze werden dabei zunächst miteinander vermischt und anschließend als Reaktionsmasse mit einem Druck von 4-6 bar in ein Werkzeug aus Aluminium, Polymerbeton oder Ureol (Kunststoff) gespritzt. Während der chemischen Reaktionen dehnen sich die Polymere aus und verdicken sich. Erst nachdem die Masse in das erhitzte Werkzeug eingespritzt wird, härtet sie aus. Dadurch wird die Produktion komplizierterer Konstruktionen als beim herkömmlichen Spritzgießen möglich. Je nach verwendetem Material können aus einem Werkzeug 50 bis 300 Teile abgegossen werden. Mit dem RIM-Verfahren können sowohl weiche als auch harte Bauteile aus Polyurethan in verschiedenen Shore-Härten, Integralschaum oder Gummiteile (Elastomer) produziert werden. In vielen Fällen stellt das RIM-Verfahren damit eine hochwertige und kostengünstige Alternative zum Spritzguss dar.

Alternative für Spritzguss

Mit Reaction Injection Molding lassen sich dünnwandige und komplexe Bauteile in kurzer Zeit fertigen, die über sehr gute optische und haptische Oberflächen verfügen. Die Bauteile sind leicht, verfügen dennoch über eine hohe Stabilität, sind flexibel, schlagzäh, besitzen gute funktionale Eigenschaften und sind temperaturresistent (bis -50 °C). Das Besondere am RIM-Verfahren ist die niedrige Viskosität, aus der größere Fließwege resultieren. So lassen sich Objekte bis zu einer Größe von 2,5 m herstellen. RIM eignet sich deshalb ideal z.B. für:

- Prototypen, Vor- und Kleinserien im Rahmen der Produktentwicklung

- Endanwendungen, wie z.B. Verkleidungsteile, Stoßfänger, Heckspoiler, Armlehnen oder Innenverkleidungen

- Hybridbauteile, wobei ein Verstärkungsbauteil in die Reaktionsmasse integriert wird

Angebot einholen >

Ansprechpartner kontaktieren >

Feinguss

Verfahrensbeschreibung

Beim Feinguss wird zunächst ein Ausschmelzmodell im 3D-Druck mittels Binder Jetting aus Kunststoff (PMMA) oder konventionell aus Wachs gefertigt. Das Modell wird an einer Gießtraube angebracht, in einer zylindrischen Stahlküvette mit Gips umgossen oder in Keramik getaucht. Es entsteht eine Grünform, die im Ofen erhitzt wird, wodurch das Modell rückstandslos ausschmilzt. In den so entstandenen Hohlraum wird im Differenzdruckverfahren flüssiges Metall eingefüllt. Nach dem Erstarren des Metalls wird die Form aufgebrochen und der Rohguss entnommen. Da die Form immer nur für einen Abguss verwendet werden kann, spricht man hier von einer verlorenen Form. Im Anschluss wird das Bauteil von der Gießtraube entfernt und kann nachgearbeitet werden. Im Feinguss lassen sich komplexe Bauteile oder Bauteile mit Hinterschnitten in einem Stück fertigen. Der Feinguss ist vor allem bei größeren Bauteilen eine interessante Alternative zur Additiven Fertigung (Laserschmelzen bzw. PBF-LB/M) und überzeugt durch seine Materialvielfalt.

Materialvielfalt für Metallbauteile

Mit Feinguss lassen sich qualitativ hochwertige Bauteile mit druckgussähnlichen Oberflächen fertigen, die sich mittels Fräsen, Polieren etc. sehr gut nachbearbeiten lassen. Die minimale Wandstärke liegt im Feinguss bei 0,8 mm, so dass sehr filigrane Bauteile produziert werden können. Feinguss eignet sich deshalb ideal z.B. für:

- Funktionsprototypen in der Automobilindustrie

- Designprototypen aus Materialien, die in der Additiven Fertigung nicht zur Verfügung stehen (z.B. Zamak)

- Prototypen für Druckgussanwendungen

Angebot einholen >

Ansprechpartner kontaktieren >

CNC-Fräsen

Verfahrensbeschreibung

CNC-Fräsen ist ein spanendes Fertigungsverfahren zur Herstellung von Bauteilen mit einer geometrisch exakt bestimmten Gestalt, wobei CNC für „Computerized Numerical Control“ steht. Auf Basis eines CAD-Modells wird computergestützt ein Werkzeug, das einem Spiralbohrer ähnelt, jedoch eine andere Schneidengeometrie besitzt, drehend gegen das Werkstück geführt, um dort Späne am Bauteil abzunehmen. Im Gegensatz zu additiven Verfahren, bei denen Material aufgetragen wird, handelt es sich beim Fräsen um ein subtraktives Verfahren. FIT setzt sowohl für die Bearbeitung von Metall- als auch von Kunststoffbauteilen auf CNC-Fräsen, wobei das Fräsen von Metallbauteilen hauptsächlich für die Nachbearbeitung von additiv gefertigten Bauteilen genutzt wird, um die nötigen Toleranzen, Oberflächenqualität und Funktionen zu erzielen. Das Fräsen aus einem Ureol-, EPP- oder Schaumblock folgt etwas anderen Regeln, denn hier kommt es vor allem auf die Schärfe des Werkzeugs und die Schnittgeschwindigkeit an, um gute Ergebnisse zu erzielen und am Ende ein passgenaues Bauteil herzustellen.

Immer passgenau

Mit CNC-Fräsen lassen sich komplexe, qualitativ hochwertige, absolut maßhaltige Bauteile herstellen.

CNC-Fräsen (Metall) eignet sich ideal z.B. für:

- Endbearbeitung von Spritzgusswerkzeugen

- Mechanische Nachbearbeitung von additiv gefertigten Bauteilen

CNC-Fräsen (Kunststoff) eignet sich ideal z.B. für:

- Prototypen für Fahrzeugaufbauten

- Lehren und Vorrichtungen

- Prototypen für Funktions- oder Crashtests

- Designteile (DKM)

Angebot einholen >

Ansprechpartner kontaktieren >

Laminieren

Verfahrensbeschreibung

Beim Laminieren, das auch als Nass- oder Handlaminieren bezeichnet wird, wird zunächst eine Formhälfte aus Kunststoffblockmaterial gefräst, deren Oberfläche nachbehandelt, versiegelt und mit einem Trennmittel versehen wird. Auf die so vorbereitete Forminnenseite wird eine Deckschicht auf Epoxid- oder Polyesterbasis gestrichen oder gespritzt. Danach werden zugeschnittene Faserlagen aus GFK-/CFK-Matten manuell per Pinsel oder Roller mit Epoxidharz getränkt und schichtweise nass-in-nass auf die Form gelegt. Dieser Vorgang wird so lange wiederholt, bis die gewünschte Wandstärke erreicht ist. Die Aushärtung der Laminate erfolgt drucklos bei Raumtemperatur. Die Bauteile werden entweder in der Form oder nach dem Entformen zusätzlich bei 50-230 °C getempert. Nach der vollständigen Durchhärtung der Teile erfolgt die weitere Bearbeitung, z.B. durch Besäumen, Schleifen, Kleben oder Färben.

Glasfaserverstärkte Kunststoffbauteile

Mit Laminieren lassen sich große und komplizierte GFK-/CFK-Formteile in hoher Qualität als Prototypen oder Kleinserien herstellen. Die Dichte des Laminats (UP-Harz) − ohne die harzreichen Deckschichten − liegt beispielsweise zwischen 1,3 g/cm³ (Glasgehalt 25 Mass.%) und 1,4 g/cm³ (Glasgehalt 35 Mass.%). Laminieren eignet sich deshalb ideal z.B. für:

- Prototypen von Segelflugzeugen, Flugmodellen, Bootsrümpfen, Seitenverkleidungen, Kühlerhauben von Traktoren

- Kleinserien im Bereich von Behälter- und Beckenauskleidungen, Blenden, Schallschutzhauben, Maschinenverkleidungen oder ganzen Maschineneinhausungen

Angebot einholen >

Ansprechpartner kontaktieren >

Weitere Links, die Sie interessieren könnten:

Metal Coating

Clever: Mit unserer professionellen Galvanisierung verleihen Sie Ihren Bauteilen kostengünstig optische oder funktionale Zusatzeigenschaften.

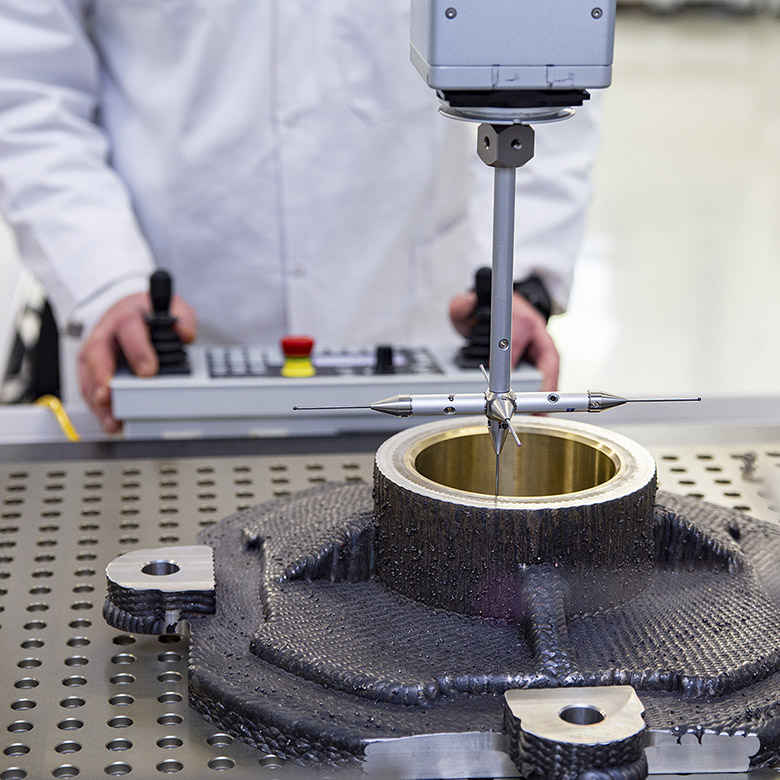

Mehr erfahren >Taktile 3D-Koordinatenmessung

Toleranzen lassen sich zuverlässig mit der taktilen 3D-Messung über präzise Messtaster eines Messsystems überprüfen.

Mehr erfahren >Innovationsguide

Ihr unverzichtbares Kompendium rund um den 3D-Druck. Hier finden Sie alles zu den verschiedensten 3D-Druckverfahren, Veredelungsmöglichkeiten, Maschinendaten und Anwendungsbeispiele aus zahlreichen Branchen.

Jetzt downloaden >