Rapid prototyping

It’s all about speed

Can you feel it too? In many industries, customer demands are continuously increasing. New and better products have to be developed, and your competition never sleeps. If you are not fast in product development, you can easily lose out. Secure your leading position by professional rapid prototyping, shorten the "time-to-market", and save money at the same time.

As one of the world's leading manufacturers, we offer you the entire value chain for the additive or conventional production of prototypes and pilot series made of plastic, metal, or building material. From the raw individual part to the fully machined and finally assembled assembly, we deliver your prototypes or pilot series right to your desk. And if you wish, also "overnight".

Concept and design models

The perfect first impression

To ensure that your product makes a convincing impression right from the start, absolutely realistic concept and design models are essential. Precision, attention to detail, and perfect surfaces are a must.

With this knowledge, we manufacture your prototypes and transform them with craftsmanship and state-of-the-art technology into products that look just like the original.

For this purpose, we offer you a wide range of post-processing options, such as:

- infiltration

- vibration grinding

- chemical smoothing

- metal coating

- vaporing

- dipping

- painting

Let us prove our efficiency in your first order - and every subsequent order as well.

Send request >

Contact us >

Functional models

Function in focus

To ensure that the use or test of your new product or an individual component is a complete success, you must be able to rely on your functional prototypes. High-quality manufacturing and processing are essential here, and that's exactly what you'll find with us.

At FIT, you have a wide range of processes and over 3,500 materials at your disposal for the production of your prototypes. This means you are completely independent of technology and can focus entirely on your requirements and wishes.

With us, you will always find the right solution, because we will advise you objectively on what is the best combination of material, manufacturing process, and post-processing technology for your application.

Send request >

Contact us >

Pilot series

No worries with small quantities

You don't want to opt for either cost or quality when producing your pilot or special series, but are looking for both, that is, inexpensive top quality?

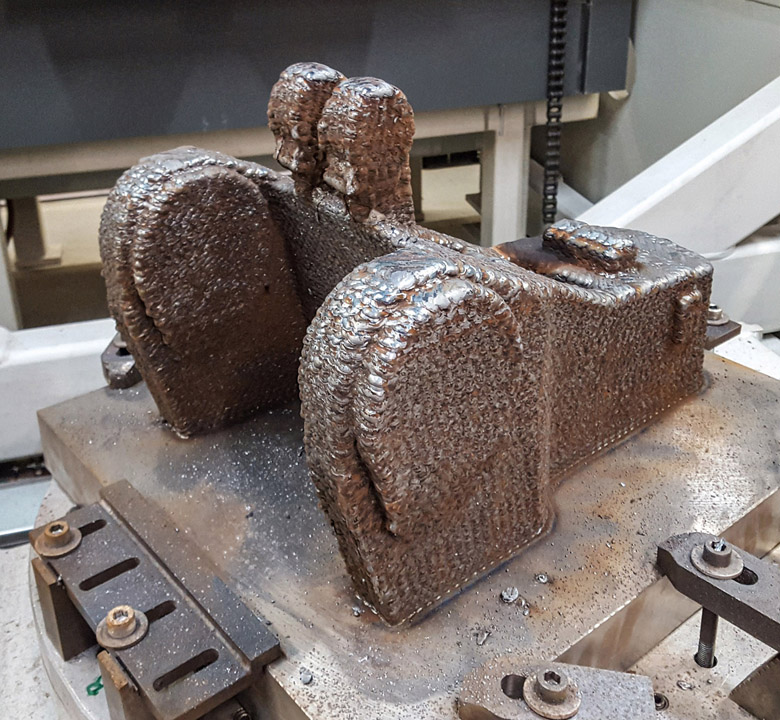

Then contact us with your small series, because we have the necessary technologies to produce low quantities cost-effectively and, if desired, in the original material.

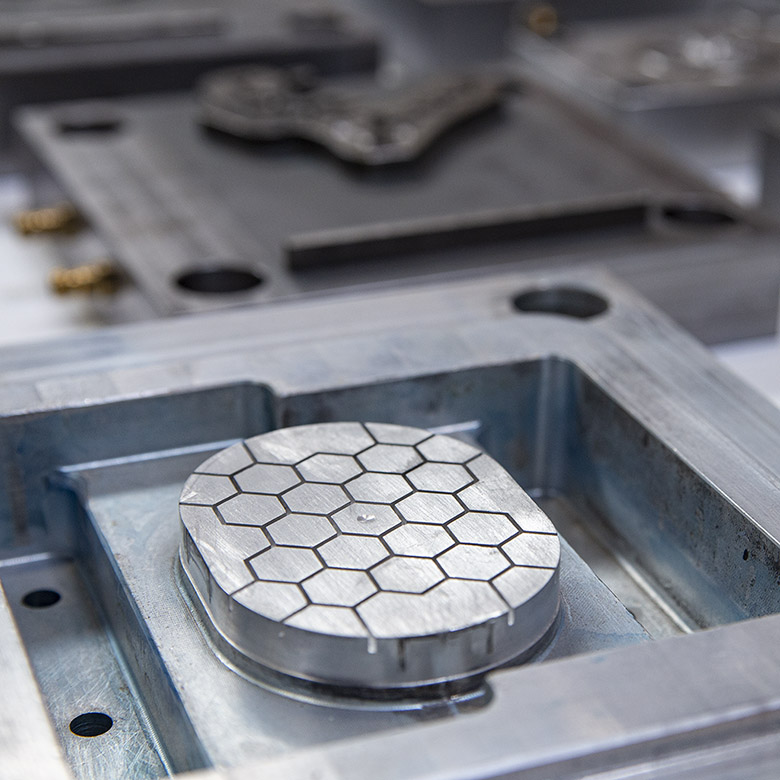

We combine the best of both worlds. Using additive manufacturing, we produce a master mold or (injection molding) tool for you. We then produce your components using conventional processes, such as:

- vacuum casting

- investment casting

- RIM

- polyamide casting

- injection molding

The best way to see for yourself is to take a look at our extensive range of options. An illustrative example is the golf tee marker that we produced for the Lauterhofen golf course as a special series. You will find the technical details and challenges in our Inspiration Book, which will be published shortly.

Send request >

Contact us >

This might also be interesting:

Rapid tooling

Learn here how you can produce tools quickly, individually, and inexpensively.

Learn more >Volume manufacturing

3D printing for series production? Is that possible? Yes! We show you how.

Learn more >Innovation guide

Your indispensable compendium on all aspects of 3D printing. Here you will find everything about the various 3D printing processes, finishing options, machine data, and application examples from numerous industries.

Download now >