News

FIT als sehr guter Lieferant für Siemens qualifiziert18.04.2024

Für einen Weltkonzern wie Siemens ist der Zugang zu Spezialexpertise bei der Herstellung innovativer Komponenten ein wichtiger Schlüsselfaktor. Aufgrund ihrer umfangreichen Fertigungskompetenz mit additiven, aber auch konventionellen und hybriden Verfahren ist die FIT AG dabei ein verlässlicher Partner für Siemens. Um im Anlauf von Geräten in Nullserie und Serie schnell und flexibel in den Markt gehen zu können, hat Siemens nun eine Qualifizierung von FIT als Lieferant im Rahmen eines Audits durchgeführt. Die Bewertung des Projekt- und Lieferantenmanagements, der Produktionsprozesse sowie des Kundendienstes und der Kundenzufriedenheit ist zur vollsten Zufriedenheit unseres Kunden Siemens ausgefallen.

Weiterlesen >

Rege Beteiligung am Fokus-Technologietag Vakuumguss06.03.2024

Am 06.03.2024 haben sich zahlreiche Besucherinnen und Besucher bei uns eingefunden, um sich über die Möglichkeiten eines oft wenig beachteten Fertigungsverfahrens zu informieren: Den Vakuumguss. Das Verfahren macht wenig Schlagzeilen, hat aber enorme Stärken sowohl für die Prototypenfertigung als auch für Klein-, Sonder- und Vorserien und setzt sich, je nach Anforderungsprofil, problemlos gegen die Benchmark-Verfahren Spritzguss und Additive Fertigung durch.

Weiterlesen >

FIT AG veröffentlicht neuen Technologieguide zu MSLA. Kostengünstige Serienbauteile aus Photopolymer14.12.2023

Innovative Technologien sind heute als Innovationstreiber aus der industriellen Produktion nicht mehr wegzudenken. Den Überblick über die Vielzahl immer neuer Technologien zu behalten ist jedoch nahezu unmöglich. Der Technologiepionier und Spezialist für Additive Fertigung FIT AG aus Lupburg bietet daher nicht nur praktische Fertigungsdienstleistungen an, sondern hat es sich zum Ziel gesetzt, sein aus jahrzehntelanger Erfahrung gewonnenes Wissen in einer Reihe von kostenlosen Guides zu teilen. Soeben ist ein Band zum MSLA-Verfahren erschienen.

Weiterlesen >

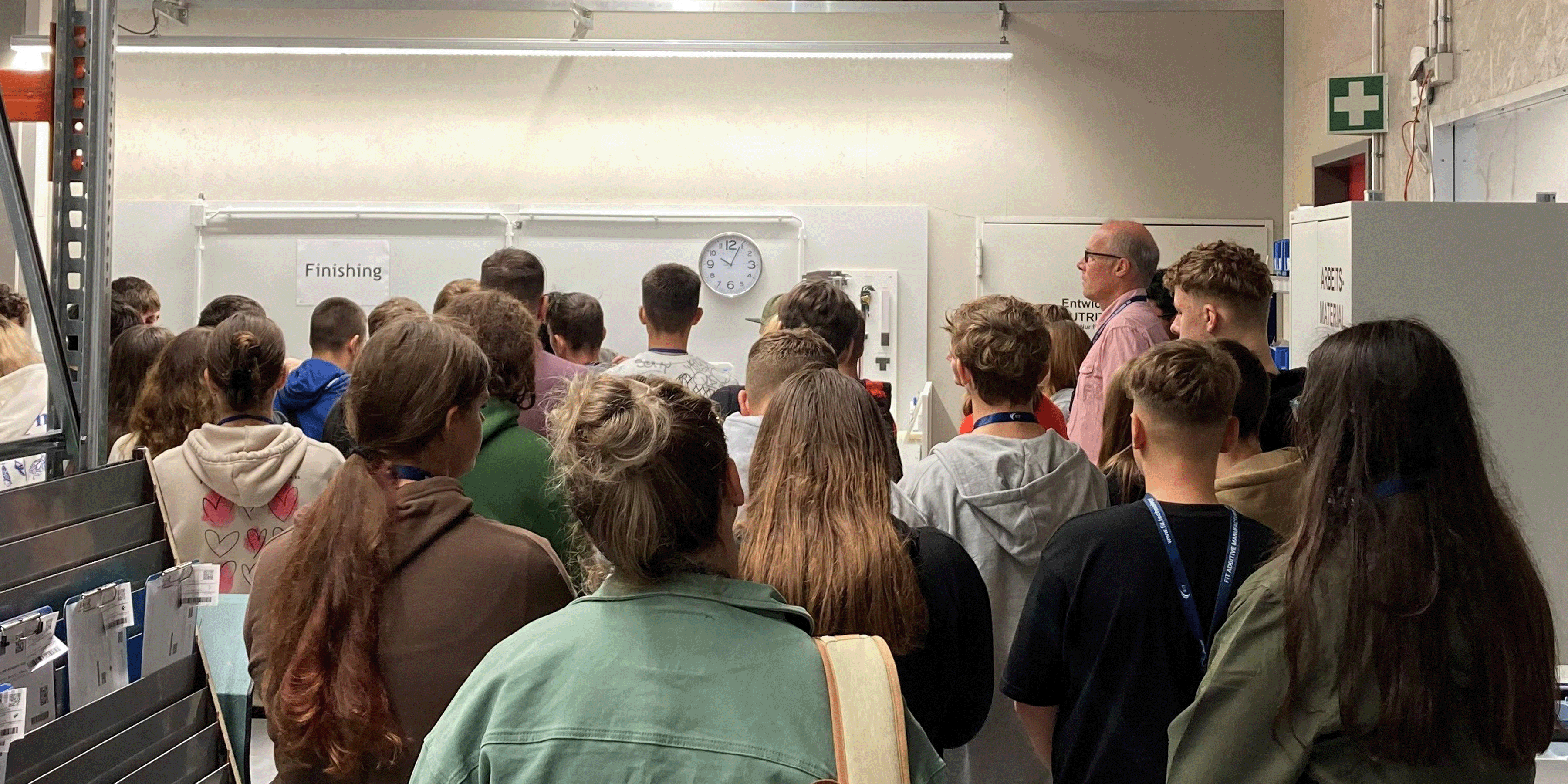

Besuch der Mittelschule Parsberg29.09.2023

Ferienjob, Schnupperpraktikum, Ausbildung: Der Nachwuchs ist für ein junges, innovatives 3D-Druck-Unternehmen wie FIT immens wichtig. Was machen wir bei FIT, wie funktioniert die Fertigung, welche Ausbildungsberufe haben wir anzubieten? Um das zu erfahren, haben uns knapp 50 Schülerinnen und Schüler der 9. Klassen der Mittelschule Parsberg besucht.

Weiterlesen >

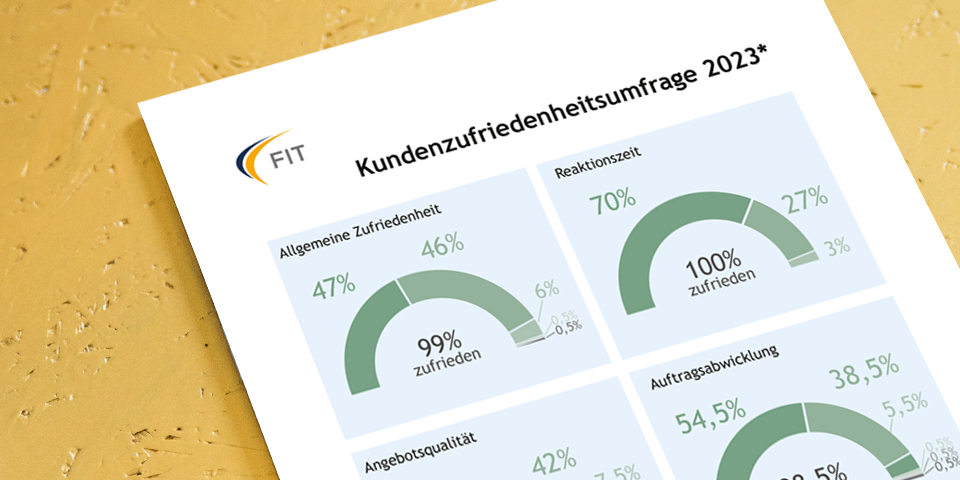

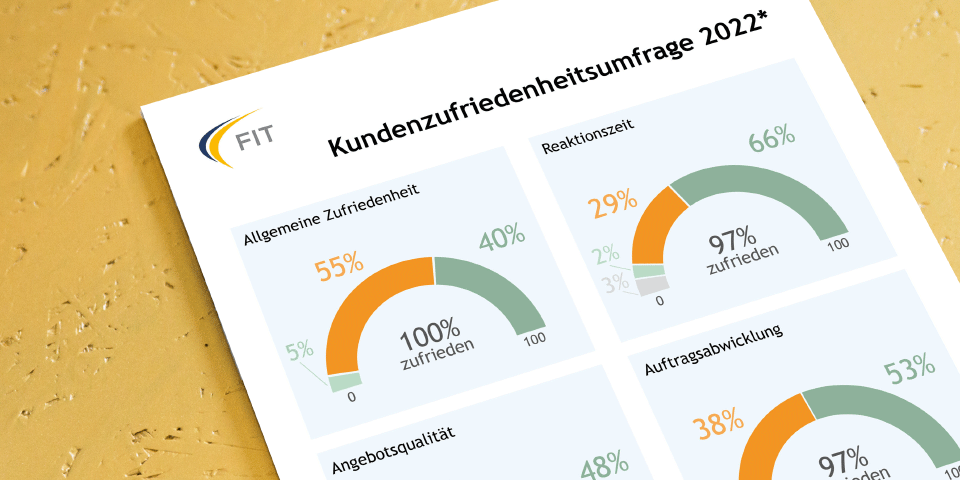

Kundenzufriedenheit für 2022 ermittelt03.05.2023

Wie jedes Jahr haben wir auch heuer wieder zu Jahresbeginn die Kundenzufriedenheit für das vergangene Jahr ermittelt. Es waren die Kunden unserer Unternehmenstochter FIT Prototyping aus dem Geschäftsjahr 2022 eingeladen, unseren anonymisierten Fragebogen auszufüllen. Hier sind die Ergebnisse: Die allgemeine Zufriedenheit liegt bei unglaublichen 100%!

Weiterlesen >

Besuch des VDI Bayern Nordost21.04.2023

Es war uns eine Freude, den VDI Bayern Nordost bei uns im Haus zu einer Firmenbesichtigung zu begrüßen. Hier sind echte Experten ihres Fachs zusammen gekommen, um sich über die aktuellen Möglichkeiten der Additiven Fertigung zu informieren. Die persönlichen Kontakte zur Industrie sind für uns selbst immer sehr motivierend, aber sie liegen uns auch aus einem ganz bestimmten Grund am Herzen: Wir wollen aufklären und ein Bewusstsein dafür schaffen, dass man vor 3D-Druck keine Angst zu haben braucht. 3D-Druck will keinem traditionellen Herstellverfahren das Wasser abgraben – ist aber in vielen Fällen ein sinnvolles, zusätzliches Tool im großen Werkzeugkoffer der Fertigung.

Weiterlesen >

Mit 3D-Druck innovative Produktideen wirtschaftlich umsetzen13.02.2023

Gemeinsam mit FIT Prototyping GmbH produziert die Gossen Metrawatt GmbH serienmäßig ein 3D-gedrucktes Zubehörteil für seine Installationstester der PROFITEST-Serie. Die additive Konstruktion des Teils ermöglicht ein Produkt mit innovativem Design und integrierten Funktionalitäten und vermeidet durch den Verzicht auf Werkzeuge klassische Fertigungsrestriktionen.

Weiterlesen >

Blitzlichtgewitter bei FIT für "vierbeinige" Stars26.10.2022

Kürzlich gab es am Wochenende Umtriebe am FIT Firmengelände. Lastwagen voll mit Equipment, Foto- und Filmkameras und zwei gut eingespielte Crews fanden sich für ein Foto-Shooting mit Videodreh in unseren Gebäuden ein. Die Protagonisten waren zumeist vierbeinig... Stühle und Tische! Vorgestellt wurde die neue Produktlinie der hochwertigen Stuhlmarke Züco Averio für den Lounge- und Konferenzbereich, die bei uns stilvoll in Szene gesetzt wurde. Der Hersteller Dauphin HumanDesign war völlig geflasht von dem Design-Ambiente der FIT und dem professionellen Ablauf. Pssst: Wussten Sie, dass man uns als Location für außergewöhnliche Anlässe mieten kann? Anruf genügt!

Nachhaltigkeits-Auszeichnung für Beton-3D-Druck-Förderung25.10.2022

Die Raiffeisenbank im Oberpfälzer Jura eG hat Mut und Weitsicht bewiesen, als sie die FIT AG bei der Realisierung der wegweisenden Technologie des 3D-Drucks von großformatigen Betonbauteilen unterstützt hat. Anwendung findet dieses schalungsfreie Verfahren für innovative Architekturprojekte. Durch vielfältige Zuschlagstoffe wie Blähglas oder Holzspäne kann das Grundmaterial gezielt neue Eigenschaften erlangen. Für die Förderung dieser innovativen Technologie beim Marktführer FIT AG wurde die Raiffeisenbank nun mit der Auszeichnung "NachhaltigkeitsGestalter" prämiert.

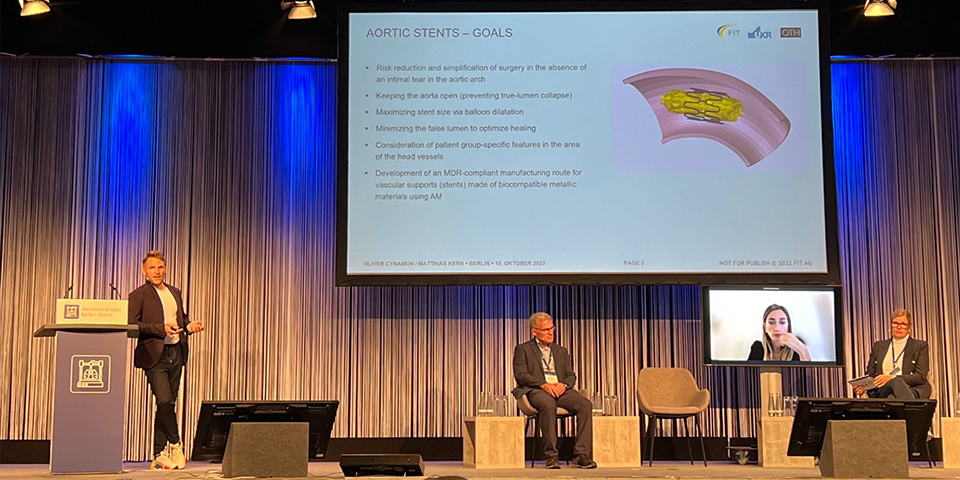

AM Medical Days 2022: Stents machen Furore20.10.2022

Auf der Fachtagung der AM Medical Days in Berlin hat Matthias Kern das innovative Stentprojekt der FIT und ihrer Forschungspartner, dem Universitätsklinikum Regensburg und der Ostbayerischen Technischen Hochschule Regensburg, vorgestellt. Das Ziel: Mit speziell designten und einem eigens für die Anwendung optimierten Verfahren, dem Micro-Laserschmelzen, leicht verformbare Aortenstents zu fertigen, mit denen die Operation einer lebensbedrohlichen Aortendissektion verbessert werden kann.

Azubis gesucht!19.10.2022

Wer bei FIT eine Ausbildung macht, ist von Anfang an auf Zukunft geeicht. Wir sind die, die mit 3D-Druck einen Haufen cooles Zeug herstellen, für E-Autos, Rennwagen der Formel 1 oder DTM, für Luft- und Raumfahrt und für Medizintechnik bis hin zu praktischen kleinen Gadgets, die das Leben einfacher machen. Ihr habt Lust was zu bewegen? Frische Ideen? Dann nix wie her! Bei uns seid ihr richtig. Auf der 18. Ausbildungsmesse des Staatlichen Beruflichen Schulzentrums Neumarkt i.d.Opf. zeigen wir Euch einen Querschnitt durch die Teile, mit denen wir die Zukunft ein wenig besser gestalten können.

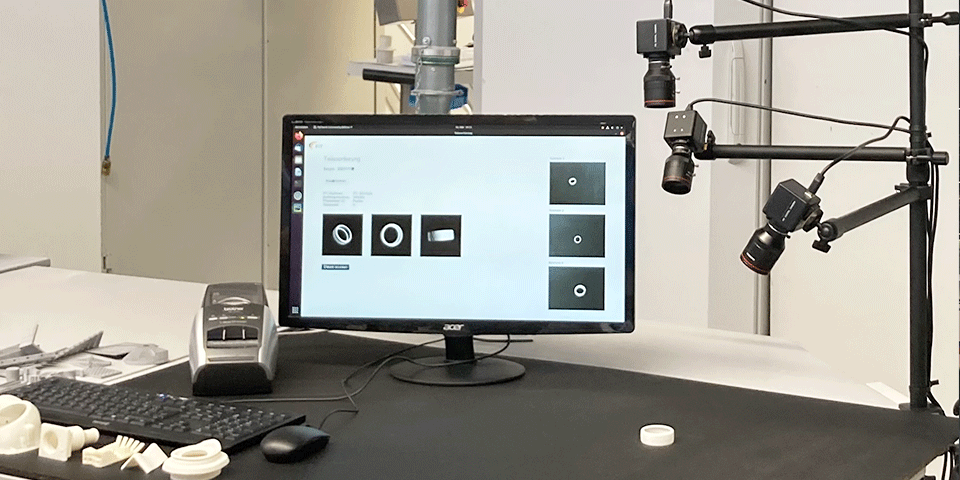

FIT am KI-Tag des Digitalministeriums28.03.2022

Am 31.03.2022 präsentiert die bayerische Digitalministerin Judith Gerlach die Ergebnisse des Förderprogramms KI-Transfer Plus. FIT stellt dabei seinen Use Case einer Anwendung Künstlicher Intelligenz im Bereich der automatisierten Bauteilidentifizierung vor, der in enger Zusammenarbeit mit der OTH Regensburg entwickelt wurde.

Kundenzufriedenheit für 2021 ermittelt16.03.2022

Wie jedes Jahr haben wir auch heuer wieder zu Jahresbeginn die Kundenzufriedenheit für das vergangene Jahr ermittelt. Es waren die Kunden unserer Unternehmenstochter FIT Prototyping aus 2021 eingeladen, unseren anonymisierten Fragebogen auszufüllen. Hier sind die Ergebnisse.

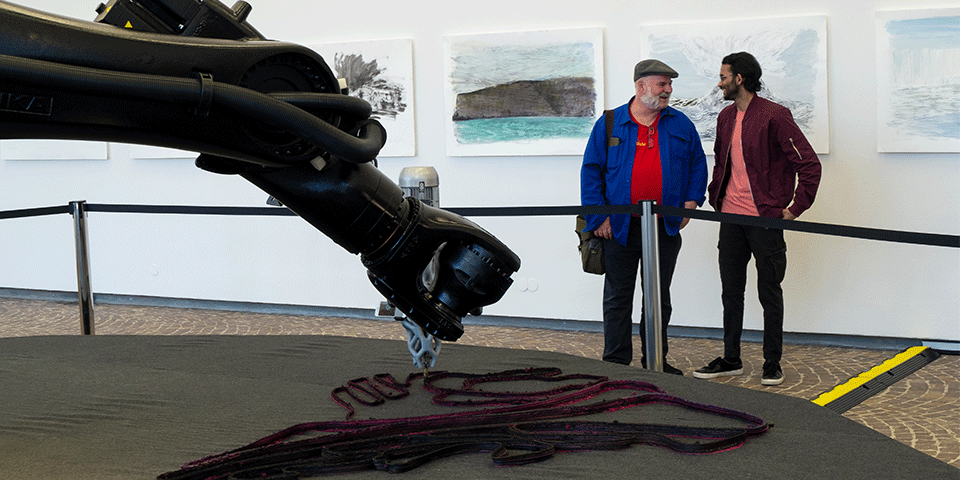

Kunst-Aktion im Sprengel Museum Hannover24.02.2022

Der Künstler Peter Lang veranstaltet im Sprengel Museum Hannover eine Aktion, die 3D-Druck und künstlerisches Schaffen harmonisch und in nie dagewesener Weise kombiniert. Titel der Aktion ist "Sker", was isländisch ist für "Es passiert". In der Einblickshalle des Museums wird ein Roboter vom 11.03. bis 29.04.2022 im 3D-Druckverfahren live mehrere Großskulpturen aus Pigment-gefärbtem Holzkunststoff entstehen lassen. Möglich wurde das Projekt durch die intensive Mitarbeit der FIT AG und ihrer auf Architektur und Kunst spezialisierten Unternehmenstochter Additive Tectonics, die sowohl in punkto Digitalisierung und Programmierung als auch 3D-Druck und Technologieentwicklung der optimale Umsetzungspartner war.

Kennen Sie schon unsere TISAX-Listung?15.02.2022

Die FIT Prototyping GmbH und die FIT Production GmbH haben umfangreiche Maßnahmen zum Schutz von sensiblen und/oder vertraulichen Informationen getroffen und sich dabei an dem Fragenkatalog zur Informationssicherheit des Verbandes der deutschen Automobilindustrie (VDA ISA) orientiert. Die Umsetzung dieser TISAX-Anforderungen (Trusted Information Security Assessment Exchange) wurde von einem externen Auditor bestätigt. Das Ergebnis ist über das Portal der ENX Association abrufbar.

Mit 3D-Druck die wirtschaftliche Umsetzung innovativer Produktideen ermöglichen13.02.2022

Gemeinsam mit FIT Prototyping GmbH produziert die Gossen Metrawatt GmbH serienmäßig ein 3D-gedrucktes Zubehörteil für seine Installationstester der PROFITEST-Serie. Die additive Konstruktion des Teils ermöglicht ein Produkt mit innovativem Design und integrierten Funktionalitäten und vermeidet durch den Verzicht auf Werkzeuge klassische Fertigungsrestriktionen.

Weiterlesen >

FIT Prototyping Partner von BRUDER10.02.2022

Wir freuen uns, der Partner von BRUDER Spielwaren GmbH + Co. KG zu sein. In ihrem neuen Imagefilm "Die BRUDER Produktentwicklung: Von der Idee zum Spielzeug" sehen Sie im Abschnitt zum Rapid Prototyping unseren Anteil an der Entstehung des Spielzeugtransporters Modell „Sprinter“.

Weiterlesen >

FIT AG mit ihrer außergewöhnlichen Architektur im Fernsehen26.01.2022

Programmtipp: Am 26.01.2021 strahlt das Bayerische Fernsehen um 22:50 unter dem Titel "Bauen für die Zukunft, Franken und Oberpfalz" einen Beitrag über die außergewöhnliche Architektur unseres FIT Bürogebäudes und unseres benachbarten Gästehauses aus. Denn bei FIT sind nicht nur die Technologien, Lösungen und Services innovativ, auch die Architektur besticht durch ein ganz außergewöhnliches Erscheinungsbild. Danach steht der Beitrag von Frieder Käsmann in der BR-Mediathek zum Abruf bereit.