3D printing for aerospace

The requirements for aerospace components are extremely high and at the same time extremely varied. The physical component properties must ensure 100% quality and safety even under high stress, while at the same time, aerospace must become more sustainable and cost-efficient.

Industrial 3D printing is an excellent production strategy to meet all these goals: Complex additive geometries allow rigorous functional integration, design freedom serves for material and weight reduction and hence fuel savings, and with special expertise such as can be provided by FIT, materials such as titanium and Inconel are also available for 3D printing.

The components produced at FIT are shining examples of the capabilities of additive manufacturing in the aerospace sector.

- Satellite bracket for fixing an optical device

- Drilling template for aircraft construction

- Fluid manifold for rocket engine

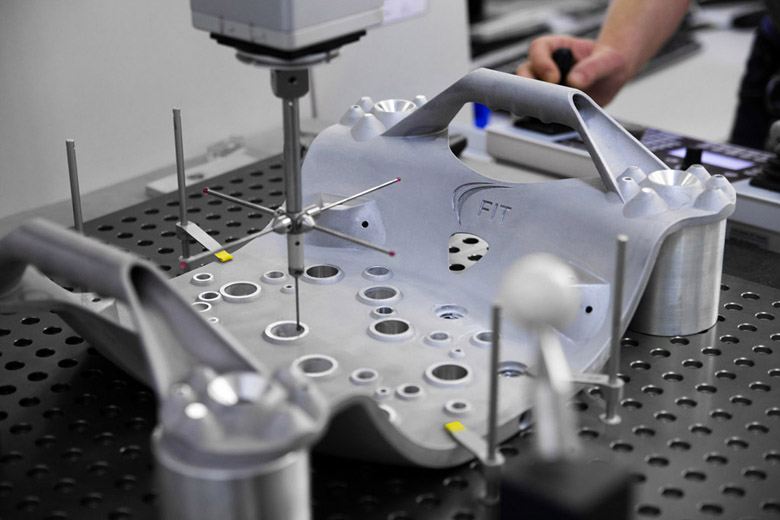

Satellite bracket for fixing an optical device

Weight is one of the central cost drivers of a space mission. Every kilogram that can be saved on a satellite reduces the cost of launching it into space by up to 25,000 euros. However, weight is even more crucial for the operation of the satellite. For example, a geostationary television satellite consumes about 0.3 liters of propellant per day to maintain its exact position. Reducing the weight of a component by one kilogram allows it to carry about one liter more fuel on its journey. This allows the satellite to last three days longer in space. If you take into account that the TV satellite's transmission power generates around 1 million in revenue per day for the operator, it is particularly worthwhile paying attention to weight in this case.

Turkish Aerospace has successfully solved these challenges for one of its satellites by using additive design and additive manufacturing: the new "Star Tracker" satellite bracket has 50% less weight, withstands 20 G, and consists of only one part instead of a previous total of 360 parts.

Send request >

Contact us >

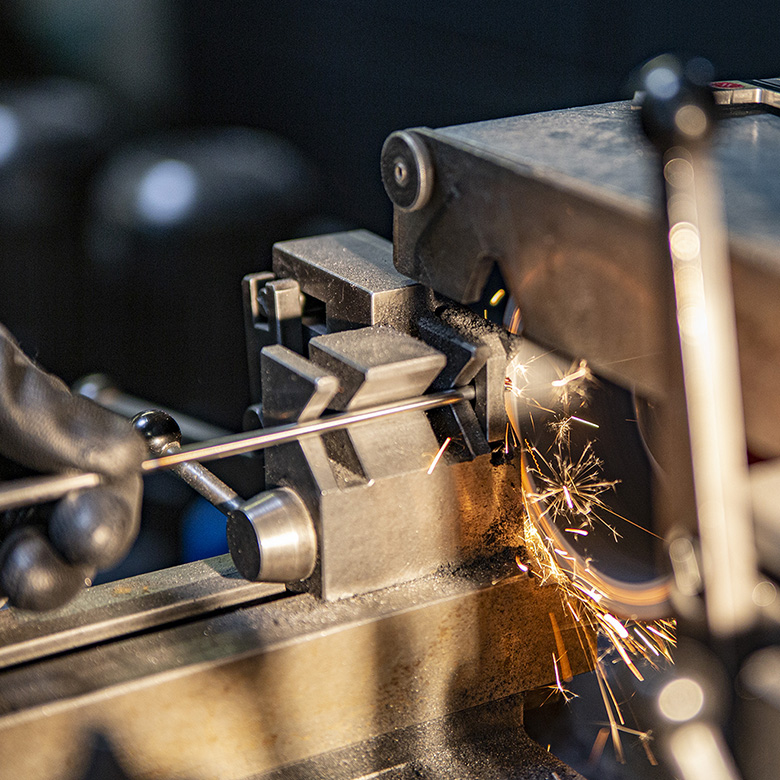

Drilling template for aircraft construction

Tools are an important issue in aviation for the assembly and maintenance of aircraft. During their use, they are subject to normal wear and tear and therefore need to be replaced regularly. But this is not the only reason for replacing tools. Changes in ergonomic specifications can also be decisive.

Ascent Aerospace was faced with exactly this and, due to time and cost constraints, decided to pursue an alternative way to optimize the ergonomics of a drill template. They found the solution at FIT.

Through a complete redesign, the weight of the drilling template was brought down to the required level. At the same time, handling was significantly simplified so that working with the tool fully met the ergonomic requirements. And all this without any compromise in terms of precision and durability.

We will be pleased to help you with such or similar challenges.

Send request >

Contact us >

Fluid manifold for rocket engine

The manufacturing costs of the rocket are a decisive factor for the success of a space company in order to keep pace with the international competition. ArianeGroup is therefore pursuing ambitious cost targets in the development of the Ariane 6 launcher, relying on innovative materials and manufacturing processes.

In this context, we were commissioned as part of the RAMS (Reliability, Availability, Maintainability, and Safety) process to manufacture a liquid distributor made of Inconel using WAAM. Through this manifold, a cold liquid oxygen-methane gas mixture flows into the combustion chamber of the Vulcain 2 engine during startup.

If you wish to know more about this project, please contact us.

Send request >

Contact us >

More interesting industries:

Automotive

Radically uniting passion and mobility: 3D printing for the vehicle of the future.

Learn more >Mechanical engineering

More efficient and customized production: Maximizing profits through 3D-printed components.

Learn more >