Additive technologies for metals

3D printing with metals is an alternative to the conventional manufacturing methods of cutting technologies such as milling and turning, and forming technologies such as casting and bending. In this way, the previous process-related restrictions can be overcome, for example with regard to complex geometries. Metal 3D printing is suitable for many applications, including high-performance applications in aerospace, medical technology, or motorsports.

In recent years, metal 3D printing has experienced very rapid growth with many technological developments. Many exciting new technologies have entered the market. At FIT, you have access to a spectrum of proven and brand-new, high-performance metal printing technologies, all embedded in the context of industry-standard, quality-controlled processes. Depending on the application and manufacturing process, the material that can be used includes metal powder and wire material in aluminum and steel alloys, titanium, copper, Inconel, and more.

- Laser melting (PBF-LB/M)

- Electron beam melting (PBF-EB/M)

- Wire arc additive manufacturing (WAAM)

- Directed Energy Deposition Laser Wire (DED-L/W)

- Submerged Arc Additive Manufacturing (SAAM)

Laser melting (PBF-LB/M)

Process description

In laser melting (LM or PBF-LB/M), metal powder is deposited layer by layer onto a build platform, with each layer heated to the melting point at specified coordinates by laser beams. By fusing the powder within a layer and across multiple layers, the component is built up in three dimensions. Unlike electron beam melting (EBM or PBF-EB/M), the build space is not preheated, resulting in a high-temperature difference between the processed and the already-cooled layers. To prevent warpage, curling, or burns on the component, support structures are therefore required to dissipate the excess energy accordingly, and these are removed again in the downstream process. To prevent oxidation during production, the build space is flooded with a protective gas. Aluminum, stainless steel, tool steel, Inconel, and copper are processed as standard materials.

Top technology for metal parts

Laser melting can be used to manufacture components with a high thermal and dynamic load capacity and which usually have better mechanical properties than castings, for example, due to the faster cooling rate. The components have a slightly rough (Ra ~20 μm), pore- and crack-free surface. Due to a minimum wall thickness of 0.3 mm, thin-walled and complex geometries are possible. Laser melting is hence ideal for e.g.:

- Cylinder heads for high-performance engines

- Lightweight components for aerospace

- Injection molding tools

New at FIT: Micro laser melting

Micro laser melting uses a much finer spot and telecentric optics to achieve minimum wall thicknesses of 20 µm to 100 µm (depending on the part). Micro laser melting is ideal for:

- Ultra-fine structural geometries, e.g. of coronary stents

- Fine mechanical applications

Send request >

Get in touch >

Electron beam melting (PBF-EB/M)

Process description

In electron beam melting (EBM or PBF-EB/M), titanium powder is melted layer by layer at defined coordinates, similar to laser melting (PBF-LB/M), but by means of an electron beam in a high vacuum and thus joined to form a component. A cathode heated to 2,500 °C emits electrons for this purpose, which are directed by electromagnetic fields and strike the metal powder at half the speed of light. In contrast to laser melting, the powder is slightly sintered before the actual melting process, which results in lower residual stress. As with laser melting, support structures are required to dissipate the energy. However, the high vacuum prevents the inclusion of oxygen, which means that the components have a higher density than in laser melting.

For high-performance applications

Electron beam melting is used to manufacture components that have extremely high thermal and mechanical load capacity as well as high corrosion resistance. The components have a very rough (Ra ~15-25 μm) surface. Due to a minimum wall thickness of 0.7 mm, thin-walled and complex geometries are possible. Electron beam melting is ideally suited for e.g.:

- Patient-specific implants in medical technology

- Thermally or mechanically highly stressed turbine or engine components in the aerospace industry

- Lightweight high-performance components for motorsports

Send request >

Get in touch >

Wire arc additive manufacturing (WAAM)

Process description

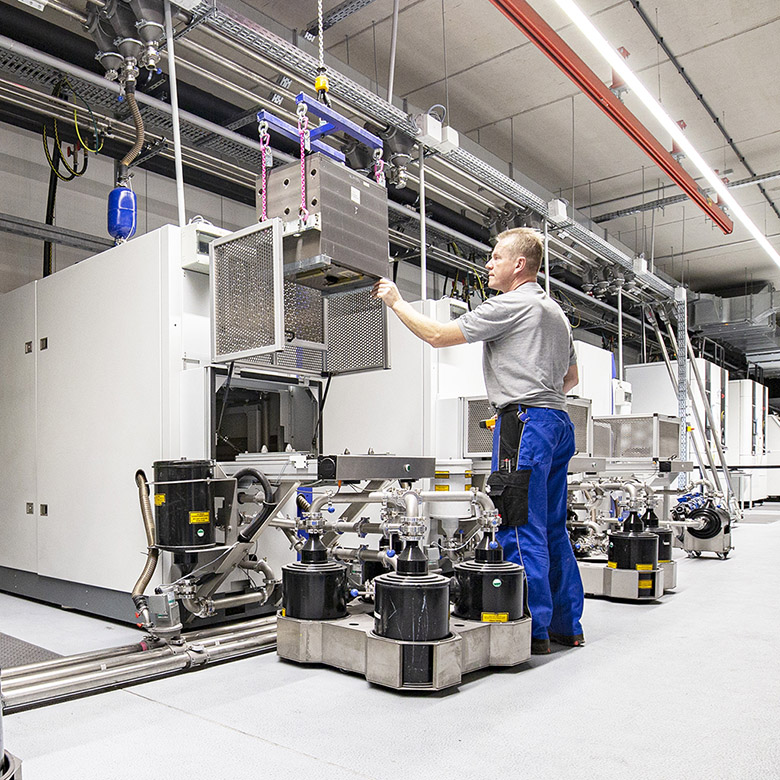

Wire Arc Additive Manufacturing (WAAM) is a wire-based technology that welds metal in layers using arc technology to build up the component additively. The technology has high deposition rates resulting in high buildup rates (600 cm³/h) as well as short production times and is impressive due to its broad material selection and low material costs. Material buildup in the machine is carried out on 3 or 5 axes, which allows complex structures or cavities. A particular advantage is the almost 100% utilization of the material. The component is produced as a near-net-shape blank, which is then finished by CNC milling either completely or partially on the required functional surfaces. This allows short delivery times.

Alternative to CNC milling

Wire Arc Additive Manufacturing is used to produce large-volume metal components (up to 3 m³) that impress with their high dimensional accuracy, low residual stress, and high structural integrity. The minimum wall thickness is 4 mm and the detail resolution is 3 mm. WAAM is particularly useful for processing high-alloy steels and materials where conventional milling is expensive and time-consuming. WAAM is ideal for e.g.:

- Brackets or covers of rail vehicles

- Bearing shields for large motors in the electrical industry (spare parts)

- Repair of damaged ship propellers

Send request >

Get in touch >

This might also be interesting:

HPHT

Get the most out of the technology: The action of pressure and temperature allows a component density of 99.99% to be achieved for metal components in hot isostatic pressing.

Learn more >Micro ct scan

Want to get an idea of the quality of the interior of the component and the invisible material structure? With us, you can have a CT scan performed in-house to know exactly what quality to count on.

Learn more >Innovation guide

Your indispensable compendium on all aspects of 3D printing. Here you will find everything about the various 3D printing processes, finishing options, machine data, and application examples from numerous industries.

Free download >