3D printing for medical technology

The department within FIT Production which specializes in medical technology unites the expertise of two professional worlds: Medical technology expertise in regulatory affairs and quality management meets more than 25 years of specialized knowledge in the field of 3D printing. With us, you get all services, from consulting, engineering and design to the actual production, professional post-processing, and quality assurance from a single source. Innovation is not a matter of chance, but the focused combination of extraordinary motivation and the appropriate means.

The geometry freedom of additive manufacturing is a great advantage for the adaptation to patient-specific anatomy, and the quick availability due to the tool-free manufacturing in the field of medical technology is another special plus in the field of medical technology. Particularly suitable for additive manufacturing are precisely fitting medical implants as well as standard titanium restorations, precisely fitting prostheses and orthoses, and patient-specific medical devices, as illustrated by the following examples:

Medical implants

It can happen anywhere, anytime: People may fall ill or get seriously injured, thus requiring a medical implant. Especially in the area of more complex joints, such as the elbow, knee, or foot joint, this is a major challenge. Standard implants quite often provide patients with unsatisfactory results, which can lead to a reduction in the quality of their life. In the worst case, there is no suitable solution at all and the joint has to be stiffened.

To improve this, a U.S. medical technology company is focusing on the rapid and reliable production of patient-specific implants, specifically using the possibilities of additive design and additive manufacturing. The design and material of the implant are specifically created to facilitate the ingrowth of the implant into the bone (the osseointegration). At the same time, an optimal fit and high compatibility are ensured. Thanks to 3D printing, the implants can be produced and inserted within a few days once required.

Would you like to learn more about this use case? Our Inspiration Book with many real use cases and all the practical and technical background information on the talus implant will be published soon!

Send request >

Contact us >

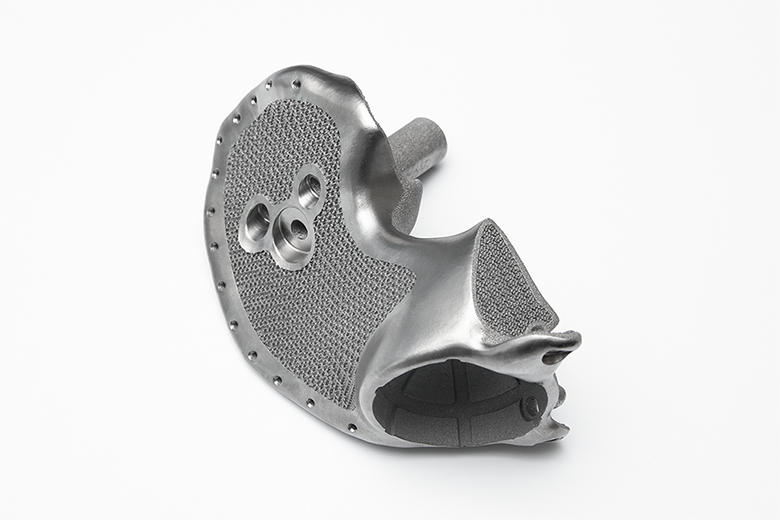

Hip implant

Hip cup

Elbow joint

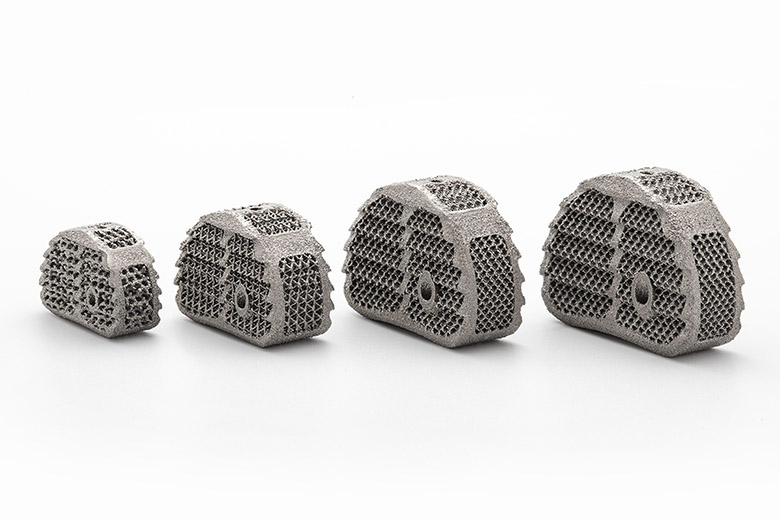

Spine cages

Prostheses

Missing limbs, e.g. as a result of disease or amputation, can be replaced by various types of prostheses to improve the quality of life of those affected. However, as with implants, standard models usually do not fit optimally.

The swimming prosthesis from F. Gottinger Orthopädietechnik GmbH is different. This is a passive prosthesis that serves to cosmetically and esthetically restore the patient's outer appearance. It is adapted to the patient's stature and proportions. The specific leg length and circumference as well as the patient's weight are parameters for the configuration. With 3D printing, the entire manufacturing process of the customized prosthesis can be digitized, from the creation of the individual data set to quality-controlled additive manufacturing. An unbeatable advantage over conventional manufacturing methods is the fast availability because from measurement to configuration and to delivery it usually takes only a few working days.

We will be happy to support you in the development and manufacture of way-leading prostheses. If you need us, we will be ready.

Send request >

Contact us >

Orthoses

For customized series production of orthoses at affordable costs, the German-based company reha team Nordbayern combines traditional production technologies with additive manufacturing.

Orthoses are orthopedic aids attached externally to the body to stabilize, relieve or correct joints and muscles. They support the functionality of the existing limbs. Unfortunately, orthoses with standard sizes usually do not fit optimally, are often very expensive and require a lot of time to manufacture. However, an improperly fitting orthotic is inconvenient in many ways, as it can hinder, rub, pinch and cause additional pain.

That's why 3D printing is also an excellent solution for orthotics in terms of fit, comfort, delivery time and cost.

You are looking for a partner for the additive manufacturing of your orthoses? Contact us.

Send request >

Contact us >

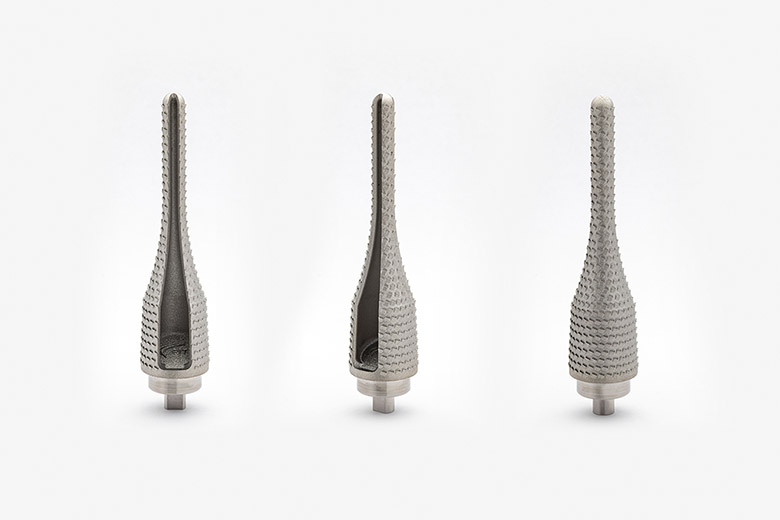

Bone graters

Bone graters are tools used during surgery to remove existing bone material for implant insertion. These graters are used once and disposed of directly after surgery. Today, bone graters are manufactured in patient-specific shapes using conventional methods. The necessary rasp structure is hammered into the metal by hand. This manufacturing process is complex, expensive, and time-consuming.

Additive manufacturing offers a better and less expensive solution. The 3D-printed grater is made from stainless steel (316L) by laser melting (LM or PBF/LB-M), freed from support and milled off, electropolished (primarily for cleaning, but also to slightly smooth the surface), and passivated to bind free radicals on the surface, thus preventing corrosion. Hollow on the inside, razor-sharp on the outside, delivered after a few days, and 100% customized.

Send request >

Contact us >

More interesting industries:

Aerospace

Creating technical progress with the aim of saving costs and weight. This is how high-tech sustainability works.

Learn more >Automotive

Radically uniting passion and mobility: 3D printing for the vehicle of the future.

Learn more >