More than a use case: our inspiration tools

This is a collection of AM use cases to demonstrate the current technological and creative state of the art of what AM can deliver to date. The showcased projects are more than references; they are what we call “inspiration tools.” Each one highlights a custom manufacturing workflow developed for one of our clients, mostly in the defense sector.

They stand as proof of our technical capabilities while demonstrating adaptable methods and principles that can be applied across a wide range of challenges. Adaptive. Scalable. Transferable. This is how we turn technical excellence into practical industrial solutions.

- Inspiration tool #1: Certified operational capability – Star Tracker bracket

- Inspiration tool #2: Optimized performance – Drill jig

- Inspiration tool #3: Improved obsolescence management – Rubber-metal bushings

- Inspiration tool #4: Clarity in critical situations – Night vision housing

- Inspiration tool #5: Optimized maintenance – Training model

- Inspiration tool #6: Improved availability – Fuel cell

- Inspiration tool #7: Every part weighs in – Load-bearing arm

- Inspiration tool #8: Increased boost – Modular structural element, TRL 4-5

- Inspiration tool #9: Enabling safety – Test fixture (differentiated)

#1: Certified operational capability – Star Tracker bracket

Customer requirement

- Extreme weight sensitivity in space applications

- High qualification cost due to component count

- Mission-critical function with the smallest batch sizes

Enabled effects

- Strategic:

Consolidating 360 parts into one reduces supply chain and qualification risks - Manufacturing:

Monolithic component eliminates assembly and alignment errors - Economic:

Major savings in test and inspection of just one part instead of hundreds, tracking of part numbers in inventory management system, faster ramp-up of production - Compliance/QM:

One qualification path, full digital traceability, simplified documentation

Specific solution of reference part

- Single-piece additively manufactured bracket (AlSi10Mg) with stiffening ribs for vibration resistance

- Survived 20G load testing in all axes.

- Successful test of the eigenfrequency behavior

- Weight reduced by 50%

Project spotlight

- Reference customer: TASUŞ

- Developed for a geostationary satellite

- Reduced complexity, improved reliability

- Ensured certification with one consolidated part

Inspiration for other applications

Any structural, optical, or sensitive mount where system-level qualification is required.

Send request >

Contact us >

#2: Optimized performance – Drill jig

Customer requirement

- Ergonomic strain and precision demands in aircraft assembly

- Drilling at height and under awkward angles

- Process compliance following aviation standards

Enabled effects

- Strategic:

Repeatable process tool for critical upgrades and retrofits - Manufacturing:

Lightweight ergonomic design improves operator precision and safety - Economic:

Eliminates rework costs from off-position drilling, significant reduction in personnel downtime costs - Compliance/QM:

Certified jig guarantees drilling within spec, reduces inspection effort

Specific solution of reference part

- Additively manufactured ergonomic jig

- Integrated handles

- Lightweight core geometry

- Certified tolerances

- Series production tool for overhead assembly processes of Airbus A321 wings

Project spotlight

- Reference customer: Ascent Aerospace

- Developed to reduce time, physical strain, and rework in cabin modifications.

- Fully integrated into an aviation-certified workflow.

Inspiration for other applications

Any assembly where precision drilling is required in confined or elevated spaces.

Send request >

Contact us >

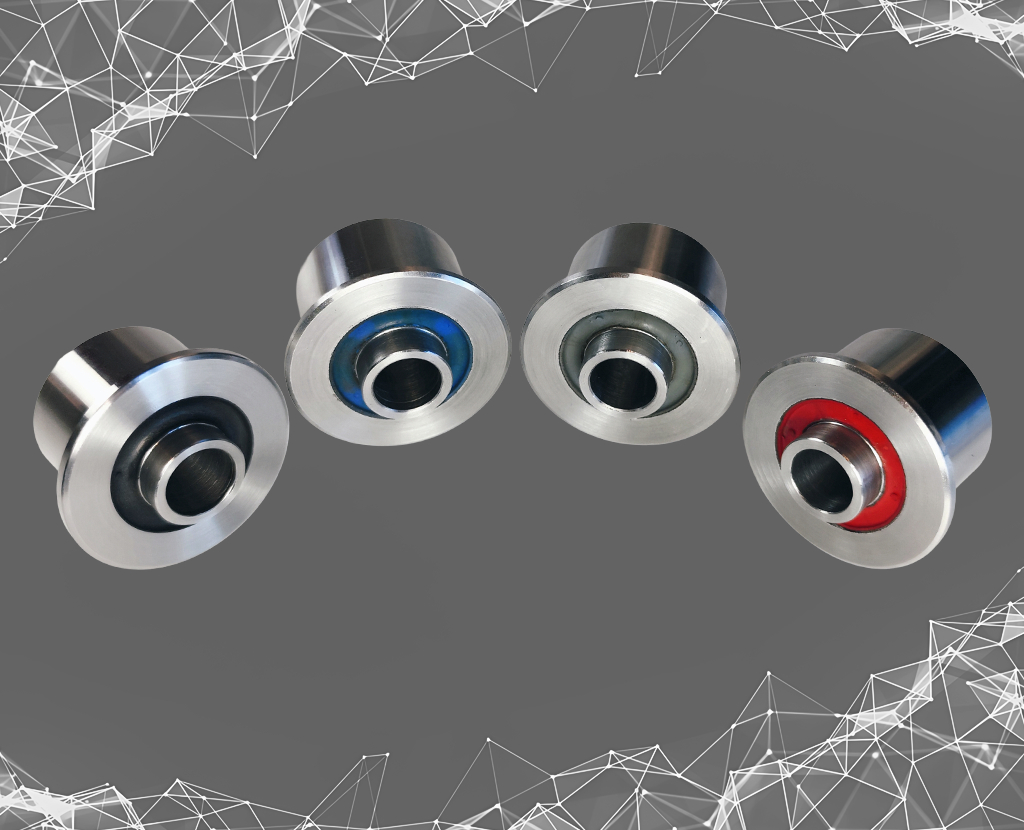

#3: Improved obsolescence management – Rubber-metal bushings

Customer requirement

- Complex geometries required for hybrid damping elements

- Low volumes and wide material variation (shore hardness, temperature, fatigue)

- Refurbishment required for legacy hardware (remould, not replace)

Enabled effects

- Strategic:

Extends lifecycle of legacy systems through targeted rubber-metal remanufacturing - Manufacturing:

Hybrid process enables removal and re-vulcanisation of elastomer layers - Economic:

Reduces replacement costs by remanufacturing rather than sourcing full assemblies - Compliance/QM:

Consistent damping values can be tailored, tested, and documented by design

Specific solution of reference part

- Rubber-metal components built or refurbished via elastomer casting onto new or cleaned metal cores

- Additive inserts enable flexible geometries without new tooling

Project spotlight

- Used in mobile defense platforms where space, durability, and comfort intersect

- Old parts restored by removing rubber and recasting

Inspiration for other applications

Any vibration-damping connection part in vehicle, defence, or industrial machinery systems.

Send request >

Contact us >

#4: Clarity in critical situations – Night vision housing

Customer requirement

- High geometric complexity and precision with robust execution

- Small series with variant requirements

- Demand-driven manufacturing without inventory costs

Enabled effects

- Strategic:

On-demand manufacturing avoids inventory and accelerates deployment - Manufacturing:

Fully functional SLS part straight from printer, no finishing or assembly - Economic:

No tool investment, even for mid-sized series - Compliance/QM:

The material and the digital process chain meet military documentation standards

Specific solution of reference part

- SLS-manufactured PA12 housing with printed connectors, functional surfaces, and fine thread

- Black coloured, mechanically stable, suitable for IP-protected electronic integration

- Delivered in short runs with flexible lead times and minimal setup

Project spotlight

- Reference customer: Send-Nods Nightvision

- Enabled manufacturer of infantry equipment to supply mission-ready systems with no molding delay

- Batch sizes produced flexibly as needed

Inspiration for other applications

All lightweight housings for sensors, communication units, or handheld tactical equipment for infantry, reconnaissance, or communication systems.

Send request >

Contact us >

#5: Optimized maintenance – Training model

Customer requirement

- Real devices too expensive or fragile for repeated training

- Need for realistic, risk-free hands-on learning

- Modular damage scenarios must be simulated

Enabled effects

- Strategic:

Enables training without equipment wear, decouples readiness from education - Manufacturing:

Additive dummy components replicate function and damage types - Economic:

Reduces cost of technician training by eliminating real-device repairs - Compliance/QM:

Training units can be standardized and documented for certification

Specific solution of reference part

- Highly realistic repair dummy replicates devices in weight, size, and functionality

- Modular parts simulate typical failures, such as broken latches, worn connectors

Project spotlight

- Reference customer: Reiser Simulations

- Developed for helicopter maintenance simulation

- Modular, robust, and intuitive to use in training centers or field academies

Inspiration for other applications

Any complex component where maintenance or repair procedures must be trained repeatedly.

Send request >

Contact us >

#6: Improved availability – Fuel cell

Customer requirement

- Uncertain market demand and rapid iteration cycles

- Need for real-use test parts without risking tooling investment

- Path from prototype to mini-series must stay open and affordable

Enabled effects

- Strategic:

Entire tool chain (CAD to mould to part) handled under one roof - Manufacturing:

AM tools used for injection moulding after vacuum casting trials - Economic:

Investment in tooling scaled with confidence, not speculation - Compliance/QM:

All production stages traceable and certifiable, even in test phase

Specific solution of reference part "JENNY 600S"

- Reference customer: SFC Energy

- Vacuum-cast prototypes followed by injection molding using AM-built tools

- Modifications done digitally without delay

- Quick ramp-up to low-volume production

Project spotlight

- Created to provide a field-compatible, compact fuel cell with flexible housing

- Path from design to function testing to small batch delivery completed within weeks

Inspiration for other applications

Any enclosure or module housing in electronics, energy, or mission equipment.

Send request >

Contact us >

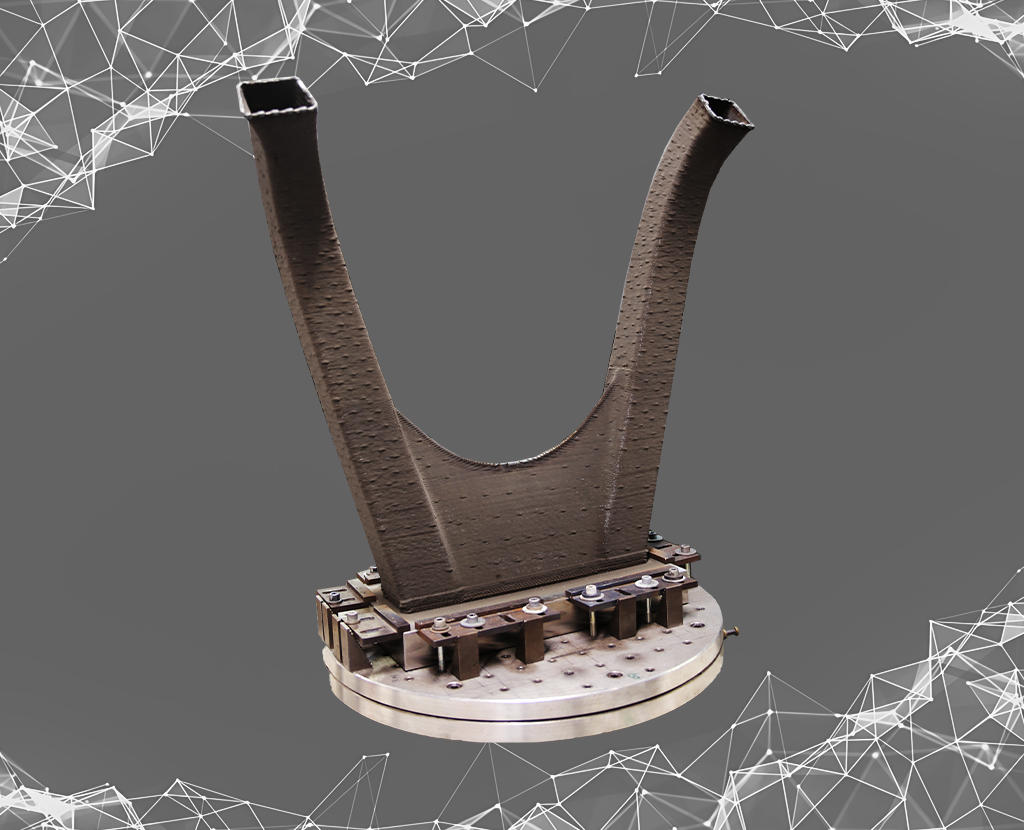

#7: Every part weighs in – Load-bearing arm

Customer requirement

- High-load structural part in a space-constrained, weight-critical environment

- Traditional welding design too heavy for modern requirements

- Production volumes too low for tooling investment

Enabled effects

- Strategic:

Weight shifted away from low-priority parts toward armor or active modules - Manufacturing:

WAAM enables geometry following stress paths, minimizing waste - Economic:

Reduced material usage and no tooling save cost per part - Compliance/QM:

Full-scale testing possible with the real final geometry

Specific solution of reference part

- Wire-Arc Additively Manufactured (WAAM) support arm in high-strength low-alloy steel (HSLA) 1.8928

- Designed via topology optimisation for vertical and lateral loads

- Passed real-use stress validation

Project spotlight

- Reference customer: KNDS

- Developed for a bridge-laying system on an armored vehicle

- Built lighter with better performance

- Lowered cost

- Shortened lead time

- Increased capacity for protected systems

Inspiration for other applications

Any support structures, frames, or linkages under variable field loads.

Send request >

Contact us >

#8: Increased boost – Modular structural element, TRL 4–5

Customer requirement

- Structural part with undefined demand and high strategic relevance

- Requires localized, secure production due to geopolitical risk

- Still in development (Technology Readiness Level 4–5)

Enabled effects

- Strategic:

Additive digital manufacturing ensures sovereign capability in any scenario - Manufacturing:

Modular geometry allows fast adaptation without full redesign - Economic:

Toolless manufacturing reduces upfront risk in pre-series stages - Compliance/QM:

From TRL 4 onwards development is executed and documented according to processes designed to support future formal certification

Specific solution of reference part

- Modular high-strength structure printed additively, optimized for pressure and shear

- Designed with certification path in mind

- Test data available for upscaling

Project spotlight

- Taurulus is a technology demonstrator for mission-resilient AM structural elements

- Flexible, certifiable, and geopolitically decoupled

- Ready for scale-up as needed

Inspiration for other applications

Any component intended for long-term readiness, depot use, or remote production logistics.

Send request >

Contact us >

#9: Enabling safety – Test fixture (differentiated)

Customer requirement

- Standards-compliant, part-specific documentation for every single unit

- No suitable off-the-shelf test equipment available; custom design and manufacturing essential

- A tight schedule leading up to system approval

Enabled effects

- Strategic:

Purpose-built test benches as a key enabler for system safety, instilling confidence before the start of series production - Manufacturing:

Precision-engineered fixtures tailored exactly to component geometry and load requirements, capable of handling complex load paths - Economic:

In-house design and manufacturing eliminate the need for external tooling – enabling rapid adaptation to design changes and significantly shorter development cycles - Compliance/QM:

Fully digital test logging, complete traceability, and reproducible test procedures meeting all relevant standards

Specific solution of reference part

- A 3D-printed, function-integrated test fixture with defined force application, built-in sensor technology, and documented component adaptation

- The design allows fast reconfiguration for new geometries while ensuring every test is recorded to the highest compliance standards

Project spotlight

- For component testing of a defense system, FIT developed a function-integrated test bench within a short time, applying mechanical loads under realistic conditions

- Documentation and traceability met all relevant standard requirements

Inspiration for other applications

Any component requiring individual proof of performance, including structural brackets, housings, and connector carriers.

Send request >

Contact us >

Relevant industries we are experienced in:

Defense

We deliver impact: Achieve maximum readiness and performance thanks to 3D printing.

Learn more >Aerospace

Creating technical progress with the aim of saving costs and weight. This is how high-tech sustainability works.

Learn more >Innovation guide

Your indispensable compendium to 3D printing. Find everything about the 3D printing processes, post-processing options, machine data, and real applications from important industries.

Download now >