3D printing for automotive

The automotive industry is in the midst of a historic transformation. New powertrains, less fuel consumption, and new comfort solutions characterize the vehicle construction of the future.

From the engine to the interior trim to the car body: with its many different technologies and materials, additive manufacturing can make decisive contributions to the reinvention of the automobile under aspects of weight reduction, aerodynamics, and noise reduction. Vehicle development also benefits from quickly available, true-to-life 3D-printed prototypes.

Our examples of real-world applications show how additive manufacturing can deliver ideal solutions to the challenges facing modern vehicles:

Console box

Few products move people as much as the vehicle of the future. Gone are the days when it was just a matter of getting from A to B quickly. Today, new concepts such as electromobility, infotainment solutions, comfort functions for the cockpit and vehicle interior, and intelligent assistance systems determine the development of modern vehicles. With additive manufacturing, you will find a toolkit that enables groundbreaking implementations for these customer requirements.

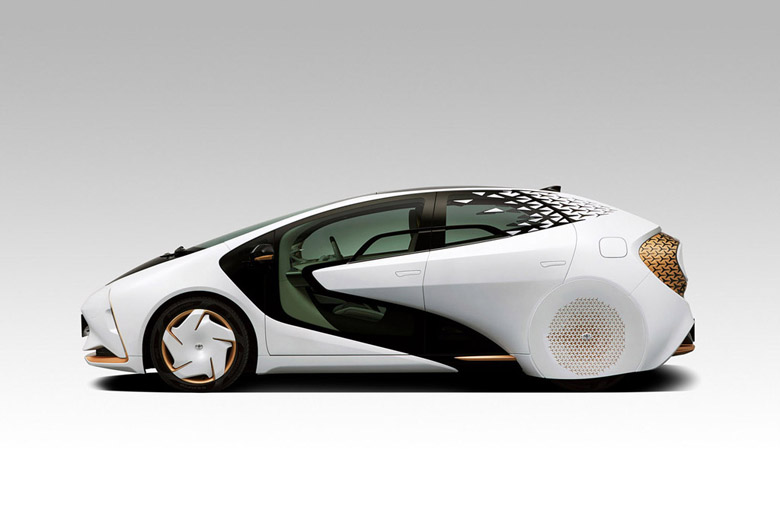

The LQ from Toyota (Toyota Motor Corporation) is a concept vehicle that uses advanced technology to create an emotional bond between car and driver. Automated driving functions and the Yui personal interactive assistant use artificial intelligence to enable a customized, emotional driving experience. The design is intended to reflect this paradigm shift in a striking way. An important element for the modern interior experience is the center console. In the LQ, it was designed as an innovative freestanding object with a shift knob and touchpad. The requirements that must be met are ergonomics in operation, robustness and the highest level of safety, flame retardancy, and weight reduction, which is crucial for consumption and range in electric drives. Internal structures provide the necessary stability while maintaining the highest level of lightweight construction. Additive design and manufacturing technology offer the best solution in terms of weight, design freedom, and reliability given this catalog of requirements.

Would you like to learn more about the console box use case, its special requirements, and the role 3D printing played in its production? Feel free to look forward to getting the Inspiration Book, which will be published shortly! Stay tuned!

Send request >

Contact us >

Outer mirror

All vehicles with electric motors strive to keep their range and consumption as low as possible. To this end, the overall weight of the vehicles is consistently reduced, and each individual component undergoes a process of weight optimization.

For the Toyota LQ, for example, the mounting of the exterior mirrors was identified as an excellent weight-saving opportunity. Optimized shaping has improved aerodynamic efficiency, as energy consumption can be reduced by keeping drag as low as possible while driving. Nevertheless, stability must be maintained even when forces are applied at higher driving speeds or in the car wash. Based on these necessary product characteristics, the design also had to blend harmoniously with the striking, innovative exterior design of the vehicle. It is pleasing to note that the new, lighter design enables even lower noise emissions.

In sum, the results of the redesign are a reduction in the number of individual parts, a noticeable reduction in weight and noise, and a modern and aesthetically pleasing detail in the vehicle's appearance.

Send request >

Contact us >

Prototypes for vehicle development

Prototypes for design studies or functional tests are an extremely important part of product development. From your own projects, you yourself know how important fast and reliable design validation is, especially for FMCG (Fast-Moving Consumer Goods) or lifestyle products to reduce time-to-market. Are you also looking for ever new ways to validate designs faster?

Multi-color and complex multi-material components are quite a challenge for prototyping in this regard. To meet the demand for transparent and true-color design prototypes with high detail resolution, for example, you have a fast, realistic and cost-effective solution at hand with the full-color PolyJet process.

For the example of a high-quality shift knob, many manufacturing steps were replaced by a printing process. The realistically grained, glossy polished burl wood, the grained leather with visible seams and the button optics give a perfect visual and tactile impression of the later original part.

The fine resolution means that the reflector structures in the glass of the tail lights are realistically formed, and the high material diversity at PolyJet also allows colored transparent models with excellent surface quality.

Send request >

Contact us >

More interesting industries:

Mechanical engineering

More efficient and customized production: Maximizing profits through 3D-printed components.

Learn more >