3D printing for art and design

For the production of artworks and design objects, 3D printing offers a unique range of new possibilities. The new manufacturing techniques enable unprecedented, fascinating applications and artistic expressions and completely reignite creativity.

In fact, the implementation of any art project with 3D printing requires a high level of technical skill; ready-made solutions usually do not exist. Depending on the project, it may be necessary to develop special algorithms, determine suitable production strategies, develop innovative materials and their parameters, and install the artwork. This will require a lot of love and dedication, but it makes it possible to implement groundbreaking artistic approaches of our time for which there is no other possibility of realization.

Here are some outstanding examples of contemporary pieces of 3D-printed art:

Cybersculpture

In the fine arts, the realization of radically new ideas often fails because of the possibilities of implementation. The geometry is too complex, the costs are too high, the material is not available, and anyway, how are you supposed to produce it?

Well, don't let your creativity be limited. There are new solutions. Additive manufacturing offers an incredible range of suitable processes for the production of artworks to create sculptures from metal, plastic, or natural materials from very small to very large dimensions.

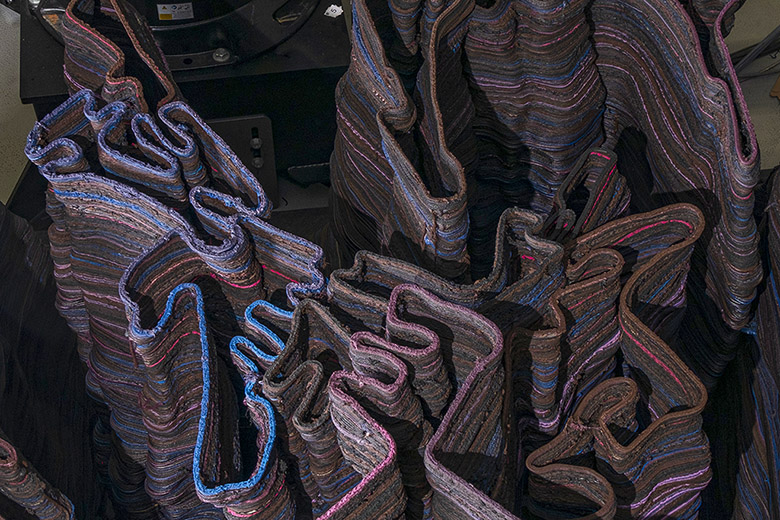

Inspired by one of his trips to Iceland, painter and printmaker Peter Lang wanted to create a work of art consisting of 27 individual parts that together form a 7.5-meter-long and 2-meter-high circular sculpture in the shape of a volcanic rock island. What's special about it is that the work was created digitally by the artist in the virtual world and was then produced live by two interacting robots at the Sprengel Museum in Hanover, Germany.

Let us show you how this exciting project was realized by our subsidiary Additive Tectonics in close interaction with the artist in our soon-to-be-published Inspiration Book!

Send request >

Contact us >

Equestrian statue

For the end of Dr. Angela Merkel's term in office, artist Wilhelm Koch had the idea of putting the former German Chancellor on a horse without saddle and bridle as the "Golden Rider". Without a pompous pose, but with a typical rhombus and trouser suit. The 2.70 meter high sculpture of the politician can be found in the middle of the lawn in front of the Tempel Museum in Etsdorf, Upper Palatinate.

The detailed, lifelike equestrian statue was made of recycled lightweight concrete coated with gold paint. SCA (Selective Cement Activation) was used for the additive manufacturing process, which allowed the artwork to be produced without formwork and without any waste.

Would you like to learn more about this project, which was realized by our subsidiary Additive Tectonics? Then we look forward to hearing from you.

Send request >

Contact us >

Church retable

When the catholic church of St. Laurentius in Altmühldorf, Southern Germany, was renovated, the parish decided to boldly modernize the entire church interior. The Munich artist duo Empfangshalle was commissioned with the implementation. Their idea: an 8-meter-high, gold-colored retable that rises as the centerpiece of the church directly behind the altar. The special feature of this sacral piece of art is its sophisticated structure, which was developed in collaboration with Studio Tessin using a computer-generated design.

There were two main challenges in creating this complex lattice structure. Due to its size, the object could not be manufactured in one piece. Therefore, the multi-part fabrication had to be cleverly planned so that the large whole could be assembled in the end. In addition, a way had to be found to give the piece a metallic appearance and golden look, even though metal fabrication was not possible for cost and weight reasons. The solution: We used polyamide and coated the surface using a specially developed technique.

Do you have a project that is similarly ambitious? Then we look forward to hearing from you.

Send request >

Contact us >

More interesting industries:

Medical technology

Are you looking for a partner for the manufacture of individual medical devices?

Learn more >Aerospace

Creating technical progress with the aim of saving costs and weight. This is how high-tech sustainability works.

Learn more >