Volume manufacturing

Quality, and nothing but quality

Do you want to delight your customers with new or improved products? Are you looking for new manufacturing processes and affordable quality?

Today, additive manufacturing can serve to fulfill individual customer wishes, develop forward-looking business models, or transform entire supply chains. Design freedom is the key to new functionalities and a distinctive look. Whether it is a single end product, a small series, or larger quantities, at FIT you will find solutions for manufacturing your series products from plastics, metals, or building materials in top quality. Without ifs and buts.

We call our solutions around the production of series parts ADM, standing for "Additive Design and Manufacturing". Take advantage of our comprehensive manufacturing capabilities for your volume components. Test us.

- Qualified single part manufacturing (ADM-Q)

- Volume manufacturing (ADM-V)

- Customized volume manufacturing (ADM-CV)

Qualified single part manufacturing (ADM-Q)

Series capability in lot size 1

Additive manufacturing is particularly convincing when it comes to manufacturing a single product. Use this strength to manufacture your unique or individual part with defined quality requirements at a low cost. A wide variety of standardized manufacturing processes are available to you at FIT for this purpose. This is what you can expect from us:

Consulting

We provide you with comprehensive advice on how we can additively manufacture your component.

Design

The know-how of our design experts is at your disposal to optimize the design of your component for additive manufacturing or, if necessary, to develop it from scratch.

Always the right technology

We offer you more than a dozen different technologies for additive manufacturing to achieve the best possible manufacturing result in terms of cost, time, and quality.

Tested quality

We produce your component on the basis of standardized manufacturing processes and conscientiously check the quality so that the product reliably meets the required properties in the end.

The example of a satellite bracket shows how this can be achieved. In the new development of one of its satellites, Turkish Aerospace faced the challenge of significantly reducing the weight of structural components without violating strict aerospace standards and guidelines. In our process use case, you can read how we manufactured a special bracket keeping these demands in mind.

Are you looking for a partner where you can manufacture your end products in lot size 1? We offer you full service for this. Please contact us.

Learn more >

Send request >

Get in touch >

Volume manufacturing (ADM-V)

Reproducible quality

When using additive manufacturing for your series production, it must be ensured that your industry-specific standards and regulations are met just as much as your individual cost and quality requirements. Especially when it comes to quality, traceability and reproducibility are crucial. At FIT, we have developed standardized and certified processes precisely for this purpose, which ensure consistent quality, regardless of whether you have 5, 500, or 5,000 products manufactured by us.

The process that needs to be developed to manufacture your product is as unique as your product. Here's what you can expect from us:

Consulting

We advise you on how you can manufacture your series products additively in the most cost- and quality-optimized way possible with regard to the design, the material and the process, or whether conventional technology or hybrid manufacturing offers better alternatives.

Design development

We create a new or adapted component geometry for you that guarantees efficient additive series production.

Process development

We work with you to develop a manufacturing process that is specifically tailored, optimized, and validated to meet the requirements of your component.

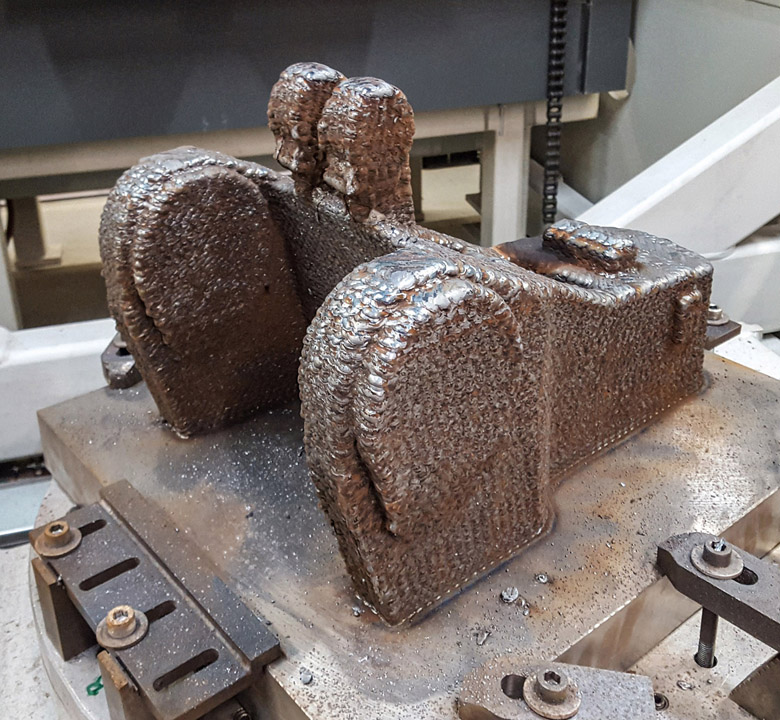

Volume manufacturing

Finally, we manufacture your series products using the selected additive technology, including post-processing, quality control, and shipping to anywhere in the world on the basis of a quality assurance agreement.

Technology transfer

If desired, we hand over the IP of the production process to you so that you can set up your own additive series production in your company.

An illustrative example of an ADM-V project is the use case of an innovative center console. Toyota relies on high-tech and a futuristic design concept for the fully electric LQ. In our process use case, read the technical details of how the center console was produced for this vehicle, which is street-legal in Japan.

Are you looking for a certified manufacturing partner for your series production? You can rely on us.

Learn more >

Send request >

Get in touch >

Customized volume manufacturing (ADM-CV)

It’s not either class or mass – it’s both!

Today's customers are increasingly demanding customized products. Particularly in the medical sector, patient-specific care with individual implants, prostheses, or ortheses is in vogue. But not only there. Other industries are also relying on this mass customization.

To enable you to participate in this trend, FIT offers you a smart solution with ADM-CV. This combines the advantages of additive series production with the possibilities of individualization so that a multitude of products can be manufactured in one go at a low cost, where every single product is unique. The basis for this is a software-supported personalization of the components, which guarantees smooth order processing, individualized series production, and error-free delivery of personalized products to your customers.

The use case of the talus implant shows how such a mass-customized series can be realized. A US-American medical technology company relies fully on patient-specific solutions for talus implants. Read in our process use case how we manage to manufacture many hundreds of implants per year in accordance with the customer's individual requirements, each of them being a unique patient-specific product.

Learn more >

You would like to individualize your product as a series product? Contact us. Together we will find a good solution.

Send request >

Contact us >

This might also be interesting:

3D-printed spare parts

Long delivery times, high costs, annoyed customers? Read here how you can rely on a virtual warehouse and be ready for action at all times.

Learn more >Art fabrication

Unleash your creativity. See how you can overcome the limits of what is possible here.

Learn more >Innovation guide

Your indispensable compendium on all aspects of 3D printing. Here you will find everything about the various 3D printing processes, post-processing options, machine data, and application examples from numerous industries.

Download now >