Technologies for your part manufacturing

Better to have more options!

Additive design allows almost limitless freedom when developing new products. However, conventional manufacturing technologies often impose tight limits on creative ideas. Break free from these restraints and expand the boundaries of what is possible. Additive manufacturing offers you a wide range of solutions and technologies for this purpose, enabling you to manufacture innovative products in a technically and economically viable manner.

In recent years, there has been a proliferation of 3D printing technologies. Even though this makes more and more possible, each technology has its strengths and weaknesses. As a technology leader, we invest in new technologies at an early stage and develop them to meet our requirements. That's why at FIT you won't find just one technology for 3D printing, but more than a dozen. So you can be sure that you will always have the best possible manufacturing technology for your application. Test us. Send us your request and you will receive your offer shortly. Benefit from our comprehensive manufacturing service.

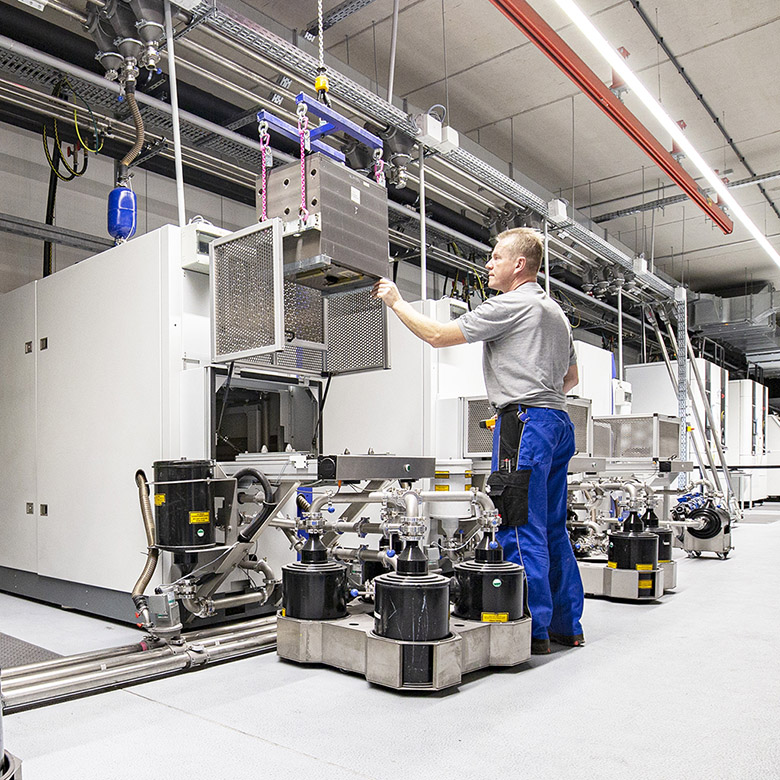

Additive technologies for metals

When milling takes too long, casting is too expensive or bending is too cumbersome, we have good alternatives: laser melting (PBF-LB/M), electron beam melting (PBF-EB/M), arc buildup welding (WAAM) or cold spray (SP3D). Metal 3D printing is suitable for many uses, including high-performance applications in aerospace, medical technology or motorsports.

Learn more >Send request >

Get in touch >

Additive technologies for plastics

If the lot size is too small, the geometry too undercut or the requirements too complex for injection molding, then you will find a variety of alternative technologies here, from DLP and FDM to GDP and SAF. With these, we produce your plastic components from resin, filament, gel or powder quickly, well and inexpensively by additive technologies.

Learn more >Send request >

Get in touch >

Additive technologies for building materials

Because construction needs to become more resource-efficient while remaining affordable, builders and architects can rely on us for pioneering technology. Our highlight: SCA is the new additive technology for the construction industry. Fast, inexpensive, environmentally friendly. And absolute freedom of geometry comes free of charge.

Learn more >Send request >

Get in touch >

Conventional technologies

3D printing is not always the single right solution to go for your part manufacturing, from a technical or business point of view. Depending on the requirements, the use of conventional manufacturing processes alone or in combination with 3D printing can make more sense. That is why you will also find, for example, injection molding, vacuum casting, RIM or elastomer manufacturing with us.

Learn more >Send request >

Get in touch >

Post-processing

3D printing is not always the single right solution to go for your part manufacturing, from a technical or business point of view. Depending on the requirements, the use of conventional manufacturing processes alone or in combination with 3D printing can make more sense. That is why you will also find, for example, injection molding, vacuum casting, RIM or elastomer manufacturing with us.

Learn more >Send request >

Get in touch >

This might also be interesting:

Laser melting

The most efficient technology for the production of series metal products.

Learn more >Selective laser sintering

The most economical technology for the production of plastic prototypes.

Learn more >