Conventional technologies

We are the specialist No. 1 for additive manufacturing. But that also means we know perfectly well that 3D printing is not the only answer to every concern. Sometimes it can be much more economical to manufacture parts of a product conventionally. Or to use the benefits of additive manufacturing for tooling rather than for part production.

That's why we also have a comprehensive catalog of conventional manufacturing techniques at your disposal so that we can always offer the best solution in terms of cost and quality.

- Injection molding

- Elastomer manufacturing

- Vacuum casting

- New: Mold One Flex

- Polyamide casting

- Investment casting

- Reaction injection molding (RIM)

- CNC milling

- Laminating

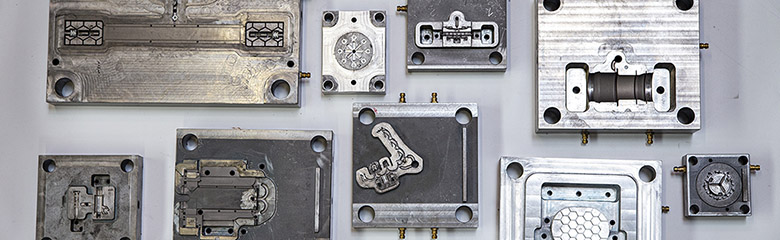

Injection molding

Process description

In injection molding, a plastic granulate is plasticized in an injection unit, i.e. heated and melted. The liquid plastic is then injected under high pressure into the cavity of the mold, whereby the cavity determines the shape and surface structure of the component. After the material has solidified, the component is removed from the mold. Undercuts can be realized by loose parts and slides. Overmolding of inserts (insert or outsert technology) is also possible. Depending on customer requirements, the molds are designed for output quantities of approx. 1,000-50,000 pieces. The special feature of FIT is the tool manufacturing, the molds are manufactured additively with laser melting (LM or PBF-LB/M) from aluminum or steel within just a few days. This helps to significantly shorten delivery times for injection molded parts.

Cost-effective series parts

Injection molding makes it possible to produce small batches with series-identical properties quickly and cost-effectively. The parts can be used directly for test purposes or the end application. For this purpose, almost any thermoplastic elastomers or engineering plastics can be processed, either monochrome or in color. Since the entire manufacturing process from mold design to mold production to the actual injection molding takes place directly at FIT, the first components can be delivered within just a few working days. Injection molding is ideal for e.g.:

- Testing the look or maturity of the design for series production

- Validation of component function

- Material tests

- Pre-series, if the series tooling is delayed or the batch size is still unclear

- Small series of components with low batch sizes

Send request >

Get in touch >

Elastomer manufacturing

Process description

Elastomer parts can be manufactured using the IM (Injection Molding) technology or the CM (Compression Molding) technology. In the IM technology, a plasticized rubber compound is injected into a heated mold and then vulcanized. For the CM technology, a vulcanization press is used to shape the molded parts using compression molds. Here, too, the components are subsequently vulcanized. Which mold and which technology are used depends on the component geometry and the quantity. Depending on the mold, output quantities of 1,000 to 100,000 pieces can be achieved. In addition to the production of molded rubber parts, FIT can also produce composite parts by overmolding metal and plastic elements such as bushings, contact sheets, threaded inserts, etc. For this purpose, the inserts are specially pre-treated to achieve an optimum bond between the insert and the elastomer material.

Flexible manufacturing

Elastomer production enables robust and (usually) flexible components with very good mechanical, chemical and optical properties to be manufactured from almost all common elastomers. The components have significantly better properties than additively manufactured rubber-like materials. Since the entire production process, from mold design to mold production to manufacturing including the post-processing steps of grinding separation planes, touching and, if necessary, polishing, takes place directly at FIT, the first components can be delivered within just a few working days. More complex compression molds can often be produced more efficiently and faster by additive manufacturing than by milling. Elastomer manufacturing is ideal for e.g.:

- Rubber wear parts

- Validation of component functionn

- Material testing

- Pre-production runs, if the production tooling is waiting in the wings or the batch size is still unclear

- Small series of components

Send request >

Get in touch >

Vacuum casting

Process description

The basis for vacuum casting is the production of a master pattern, which is manufactured in 3D printing using stereolithography (SLA). The master pattern is fixed in a frame after the mold separation, sprue and risers have been determined. The frame is then poured with a 2K silicone. After the silicone has cured, the silicone mold is cut open with a scalpel along the defined mold parting line and the master pattern is removed. A multi-component PU resin (polyol + isocyanate) is filled into this empty silicone mold in a vacuum casting machine under vacuum to avoid air pockets. After casting, the mold is placed in an oven to cure. The parts produced in this way are removed from the mold after a material-dependent demolding time and finished. The mold is then available for further castings. Die Ausbringmenge ist abhängig von der Bauteilgeometrie sowie dem Abgussmaterial und liegt auftragsabhängig für Prototypen und Klein- und Sonderserien zwischen 15 und 500 Teilen je Form. The output quantity depends on the part geometry, casting material, and requested lot size for prototypes or small batch and special series, ranging between 15 to 500 parts per mold.

Small quantities in top quality

Vacuum casting is used to produce detailed components from a wide range of PU resins. The components have surfaces that are comparable in quality to injection molding and can be finished very well. This makes vacuum casting a fast, precise, and cost-effective alternative to additive manufacturing and injection molding. Vacuum casting is ideal for e.g.:

- Pre-series and small series as part of product development

- Production of series tools

- Product samples

- Prototypes for fit and function tests

- Design and trade show models

- Spare parts or small series for end applications, e.g. linings, covers, housings

- Translucent containers and transparent displays

Send request >

Get in touch >

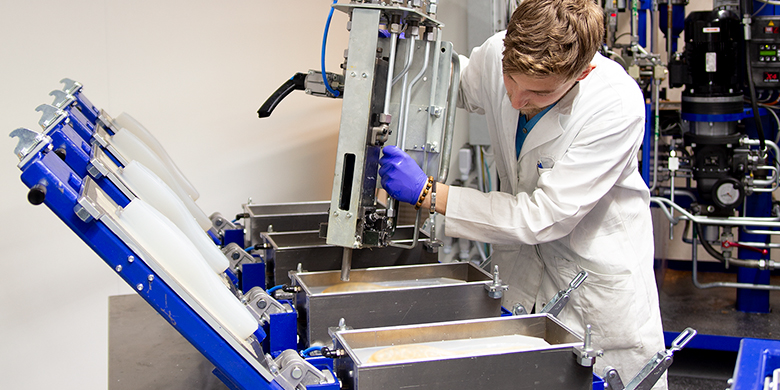

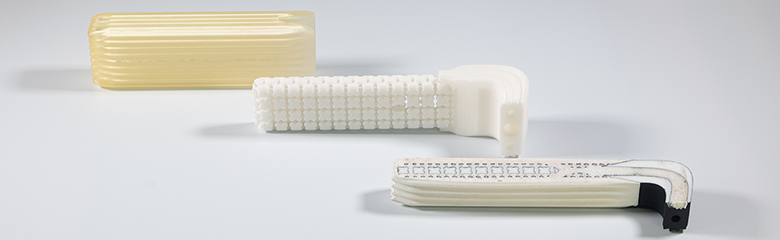

NEW: Mold One Flex

Process description

In foam injection molding, liquid PU materials such as isocyanate and polyol are mixed and the reaction mass foams up in the mold of the high-pressure foaming system at a pressure of 0.8 bar. The mold and the component are then cured in a heating oven. The foam density can be controlled very well depending on the mixing ratio. A standard value is 0.38 g/cm³.

The special feature of the Mold One Flex hybrid process is the combination of innovative additive and proven conventional manufacturing methods. A one-off mold is produced for each component using the MSLA process. MSLA materials have the advantage that the molds can be produced quickly, cost-effectively, and with high capacities as well as individualized and can be removed from the component very easily in a crushing process due to the brittle material properties.

Alternative for injection molding

PU foams have an excellent insulating and damping effect and are ideal for e.g:

- Individualized mass products such as shoe soles

- Upholstery

- Insulating materials

- Shock protection for wearing parts

Send request >

Get in touch >

Polyamide casting

Process description

The basis for polyamide casting, similar to vacuum casting, is the production of a master model, which is manufactured in 3D printing using stereolithography (SLA). The master pattern is fixed in a frame after defining the mold separation, sprue and risers. A 2K silicone is then poured into the frame. After the silicone has cured, the silicone mold is cut open along the specified mold parting line with a scalpel and the master pattern is removed. In a vacuum casting machine, a monomer is enriched with additive and catalytic components and filled into the silicone mold under vacuum for polymerization. This avoids air pockets. After casting, the mold is placed in an oven to cure. The parts produced in this way are removed from the mold after a material-dependent demolding time and undergo post-processing as specified. The mold is then available for further castings. The output quantity depends on the part geometry and the casting material and is between 10 and 15 parts per mold.

Near-series plastic parts

Polyamide casting can be used to produce plastic components with thermoplastic materials (PA 6) that have near-series properties (injection molding) and significantly better chemical, thermal and mechanical properties than vacuum casting. If desired, the components can be post-processed, painted in almost any color or electroplated with copper or nickel (metal coating). PA casting is ideal for e.g.:

- Functional prototypes for endurance tests

- Complex prototypes with high dimensional accuracy (approx. +/- 0.3 %), such as intake flanges, guides, levers or housings

- Small series or preliminary series, e.g. in mechanical engineering for sliding elements, spindle nuts or chain conveyor belts

Send request >

Get in touch >

Investment casting

Process description

In investment casting, a cast-out model is first produced in 3D printing using binder jetting from plastic (PMMA) or conventionally from wax. The model is attached to a casting screw, cast around with plaster in a cylindrical steel flask or dipped in ceramic. A green mold is created, which is heated in the furnace, causing the model to melt out without leaving any residue. Liquid metal is poured into the resulting cavity using the differential pressure method. After the metal has solidified, the mold is broken open and the raw casting is removed. Since the mold can only be used for one casting at a time, this is referred to as a "lost mold". The component is then removed from the casting screw and can be post-processed. It is possible to manufacture complex components or components with undercuts in one piece. Investment casting is an interesting alternative to additive manufacturing (laser melting or PBF-LB/M), especially for larger components, and is impressive for its material diversity.

Material diversity for metal components

Investment casting can be used to produce high-quality components with surfaces similar to die casting, which can be very easily finished by means of milling, polishing, etc. The minimum wall thickness in investment casting is 0.8 mm, so that very filigree components can be produced. Investment casting is ideal for e.g.:

- Functional prototypes in the automotive industry

- Design prototypes made of materials that are not available in additive manufacturing (e.g. zamak)

- Prototypes for die casting applications

Send request >

Get in touch >

Reaction injection molding (RIM)

Process description

Reaction injection molding, also known as low-pressure injection molding, is used for the production of plastic molded parts. Polyol and isocyanate (an optionally, other additives) are mixed together and then injected as a reaction mass at a pressure of 4-6 bar into a mold made of aluminum, polymer concrete or ureol (plastic). During the chemical reactions, the polymers expand and thicken. The mass hardens after it has been injected into the heated mold. This makes it possible to produce more complicated designs than with conventional injection molding. Depending on the material used, 50 to 300 parts can be gained from one mold. The RIM technology can be used to produce both soft and hard components from polyurethane in various shore hardnesses, integral foam or rubber parts (elastomer). In many cases, the RIM process represents a high-quality and cost-effective alternative to injection molding.

Alternative to injection molding

Reaction Injection Molding is used to produce thin-walled and complex components in a short time, with very good optical and haptic surfaces. The components are lightweight, have high stability, are flexible, impact resistant, have good functional properties and are temperature-resistant (down to -50 °C). The special feature of the RIM technology is its low viscosity, which results in longer flow paths. This means that objects up to a size of 2.5 m can be produced. RIM is ideal for e.g.:

- Prototypes, pre-series and small series as part of product development

- Hybrid components, where a reinforcing component is integrated into the reaction mass

Send request >

Get in touch >

CNC milling

Process description

CNC milling is a metal-cutting manufacturing process for the production of components with a geometrically precisely defined shape, with CNC standing for "Computerized Numerical Control". Based on a CAD model, a tool that resembles a twist drill but has a different cutting geometry is guided against the workpiece by computer to remove chips from the component. In contrast to additive technologies, in which material is applied, milling is a subtractive technology. FIT relies on CNC milling for both metal and plastic parts, with milling of metal parts used primarily for post-processing additively manufactured parts to achieve the necessary tolerances, surface quality and functionality. Milling from a block of Ureol, EPP or foam follows slightly different rules, because here the main factors are the sharpness of the tool and the cutting speed in order to achieve good results and produce a precisely fitting component.

Always a perfect fit

CNC milling is used to produce complex, high-quality, absolutely dimensionally accurate components

CNC milling (metal) is ideal for, for example:

- Post-processing of injection molds

- Mechanical post-processing of additively manufactured components

CNC milling (plastics) is ideal for e.g.:

- Prototypes for vehicle bodies

- Gauges and jigs

- Prototypes for functional or crash tests

- Design parts (DKM)

Send request >

Get in touch >

Laminating

Process description

For laminating, a mold half is first milled from a plastic block material, the surface of which is post-processed, sealed and provided with a release agent. A top layer based on epoxy or polyester is painted or sprayed onto the inside of the mold. Then, cut-to-size fiber layers of GFRP/CFRP mats are manually impregnated with epoxy resin by brush or roller and placed wet-in-wet on the mold in layers. This process is repeated until the desired wall thickness is achieved. The laminates are cured without pressure at room temperature. The parts are either annealed in the mold or additionally at 50-230 °C after demolding. After the parts have cured completely, further processing is carried out, e.g. by trimming, grinding, gluing or painting.

Glass-fiber-reinforced plastic components

Laminating is used to produce large and complicated GRP/CFRP molded parts in high quality as prototypes or small batches. The density of the laminate (UP resin) - without the resin-rich cover layers - is, for example, between 1.3 g/cm³ (glass content 25 mass.%) and 1.4 g/cm³ (glass content 35 mass.%). Lamination is ideal for e.g.:

- Prototypes of gliders, model airplanes, boat hulls, side panels, radiator hoods of tractors

- Small series in the field of tank and basin linings, screens, sound insulation hoods, machine cladding or entire machine enclosures

Send request >

Get in touch >

This might also be interesting:

Metal coating

Clever: With our professional electroplating, you can give your components additional optical or functional properties at low cost.

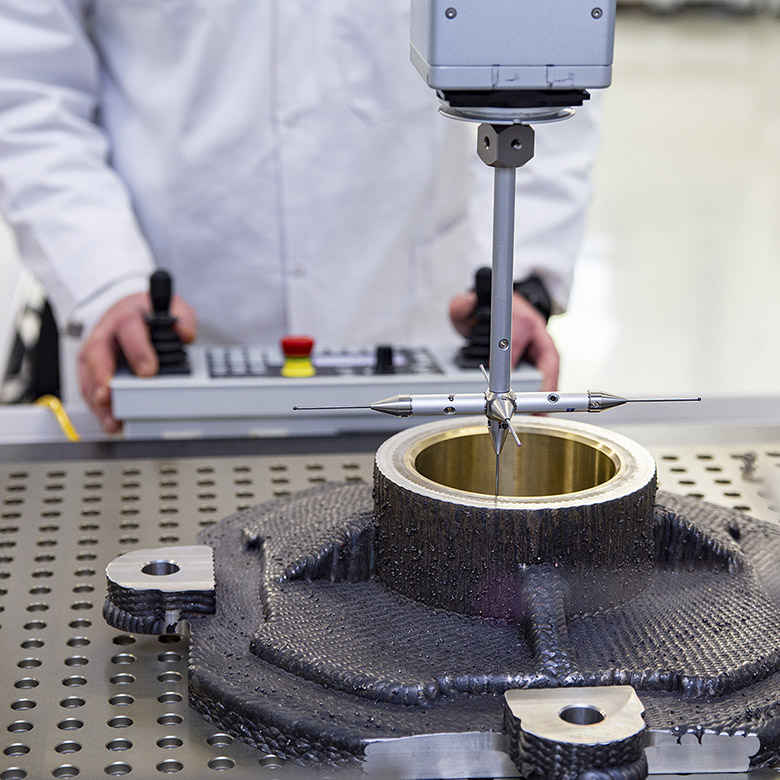

Learn more >Tactile 3D coordinate measuring

Tolerances can be reliably checked with tactile 3D measurement using precise measuring calipers.

Learn more >Innovation guide

Your indispensable compendium on all aspects of 3D printing. Here you will find everything about the various 3D printing processes, post-processing options, machine data and application examples from numerous industries.

Free download >