Additive technologies for plastics

3D printing with plastics is the classic. A high range of different manufacturing processes has emerged since the invention of 3D printing.

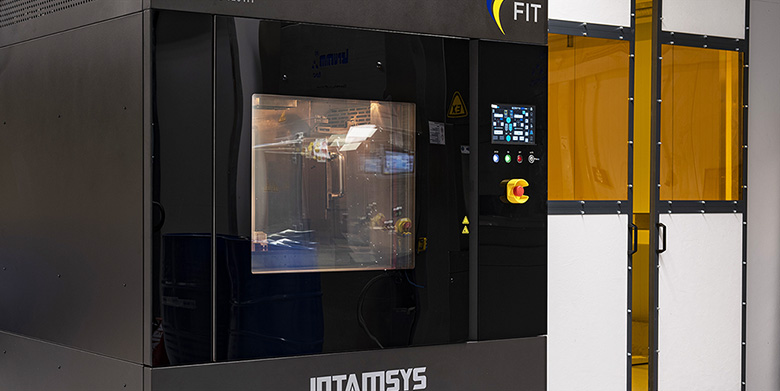

At FIT, you have access to an extensive machine park with an abundance of machines from a wide range of manufacturers, from established technologies in high capacities to special technologies. With every technology we offer, you can rely on our expertise: The technologies are validated and all processes are subject to sophisticated quality control.

The range of materials is also extremely diverse, constantly being expanded, so that the right material properties can be achieved for almost any application. FIT uses powder, granulate, filament, and resin. This gives us ultimate flexibility in the choice of input materials for every purpose.

- Selective laser sintering (PBF-LB/P)

- Stereolithography (SLA)

- Masked stereolithography apparatus (MSLA)

- Digital light processing (DLP)

- Selective absorption fusion (SAF)

- PolyJet

- Fused deposition modeling (FDM)

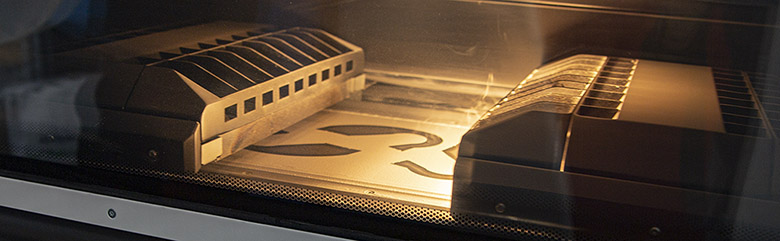

Selective laser sintering (PBF-LB/P)

Process description

In selective laser sintering (SLS resp. PBF-LB/P), as in all laser powder bed fusion technologies, the plastic powder is deposited over the entire surface of a build platform. A CO2 laser heats the plastic particles at predefined coordinates almost to their melting point, causing them to bond together. Once a layer has been produced, the build platform is lowered, a new layer of powder is applied and the component is thus produced in three dimensions. Unlike stereolithography (SLA) or the PolyJet technology, complex geometries with undercuts or overhangs can be built without support structures, because the components are supported by the surrounding material in the compact powder bed due to the high heat in the build space. This means that, for example, interlocking moving parts can also be manufactured in one piece.

Top technology for plastic parts

Selective laser sintering is used to produce components that have a high-temperature resistance and whose good mechanical properties do not age over their lifetime, either. The components have a relatively rough (Ra ~13 μm), grainy surface that can be very easily post-processed. Due to a minimum wall thickness of 0.7 mm, thin-walled and complex geometries are possible. SLS is ideal for e.g.:

- Lightweight and customized orthoses and prostheses in medical technology

- Prototypes for the automotive industry

- The on-demand production of hard-to-find spare parts for the rail industry

Send request >

Get in touch >

Stereolithography (SLA)

Process description

In stereolithography (SLA), the first and longest-used 3D printing process, a duroplastic synthetic or epoxy resin (photopolymer) is cured by an ultraviolet laser beam guided along the component contours via movable mirrors. Once the layer is completely cured, the build space is lowered, a new layer is applied and the entire component is thus built up in three dimensions. Support structures are required to fix the components in the liquid build space, and these are removed manually afterwards. Depending on the material, a curing process is then carried out using UV treatment to completely solidify the outer surface of the components. Since the material is constantly sensitive to light, discoloration of the components occurs over time, which is why post-treatment of the surfaces may become necessary.

Filigree structures and top surface quality

Stereolithography is used to produce highly isotropic, waterproof, and temperature-resistant components with a very high detail resolution, accuracy, and very smooth surfaces (Ra ~2 μm). Due to a minimum wall thickness of 0.7 mm, thin-walled and complex geometries are possible. SLA is ideal for e.g.:

- Design and concept models within the scope of product development

- Functional prototypes for testing the accuracy of shape or fit

- Tooth or jaw models for the production of implants or braces

- Ear molds for the hearing aid industry

- The production of master models (e.g. for vacuum casting)

Send request >

Get in touch >

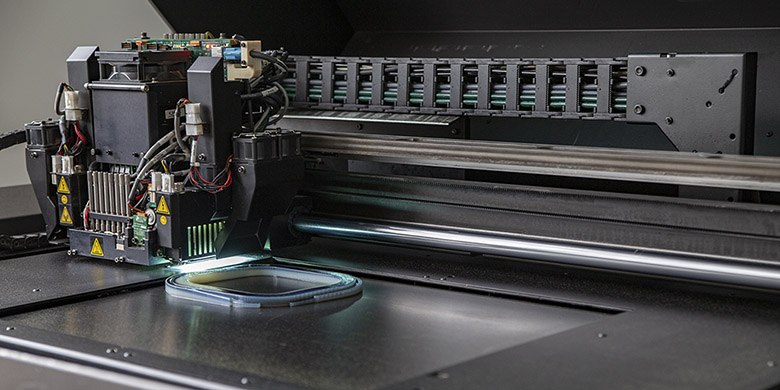

Masked stereolithography apparatus (MSLA)

Process description

MSLA (masked stereolithography apparatus) is a process from the family of resin-based 3D printing technologies and combines the principle of stereolithography with state-of-the-art display technology to create precise and high-resolution models. The central element of the MSLA process is an LCD display that serves as a shadowing mask, allowing partial exposure to the liquid material. The screen is located between the light source and the container filled with photosensitive resin. It is only permeable to the UV light at the areas defined for the respective component production. At the exposed areas, the resin reacts to the UV light and cures by polymerization. Once a layer is completed, the build platform is raised by 50 μm and the process is repeated for the next layer until the object is fully built. The resin that remains liquid can be reintroduced into the production process in a purified state.

Extremely high detail resolution

A key advantage of the MSLA process is its speed as the entire resin basin is exposed per print run rather than having to traverse the part contours from one laser spot as in traditional SLA processes. Thanks to the new 12K display technology, MSLA offers an impressive resolution. This allows parts with complex geometries and the finest details to be produced with perfect surfaces. Due to the tool-less production, MSLA is in many cases an economically attractive alternative to injection molding. MSLA is hence ideal for e.g.:

- Series parts

- Individualized pin sleeves

- Special designs for spray and protective caps

- Fashion, spectacle frames, and costume jewelry

- Disposable molds for molded foams with very good surfaces

Send request >

Get in touch >

Digital light processing (DLP)

Process description

Digital Light Processing (DLP) uses a liquid photopolymer that is cured by UV light projection. In contrast to stereolithography (SLA), the light does not penetrate the material from above, but from below through the transparent base of the build plate (bottom-up process). The component is thus exposed to light layer by layer and pulled upwards out of the build space. In the DLP process, the resolution of the components is defined by the production volume (size of the resin tank) and the resolution quality of the light source (projector). The higher the resolution of the light source and the thinner the layers, the finer the level of detail of the component. As the material is exposed to light over its entire surface, higher build-up rates are possible with DLP than with SLA. After production, the components are usually thermally post-cured. In addition, geometry-dependent support structures are mechanically removed. DLP is currently used in numerous industries, such as dental technology, the jewelry industry, and aerospace.

Perfection in detail, also for series production

With DLP, components can be produced at a build rate of up to 100 mm/h with an extremely high level of detail, sharp contours, and very smooth surfaces. Due to the variety of materials available, solid and durable materials with thermoplastic-like behavior as well as rubber-like, castable, heat-resistant, and biocompatible materials can be processed precisely and without tools. In this respect, DLP is a real alternative to conventional injection molding, not only in terms of quality but also for cost reasons, and is ideal for the production of:

- Prototypes with high demands on surface quality

- Small or pilot series made from high-performance material

- Mold or tool making

Send request >

Get in touch >

Selective absorption fusion (SAF)

Process description

The new SAF technology uses a bed of polyamide powder, as in selective laser sintering (PBF-LB/P). However, the layer-by-layer bonding of the powder particles is not achieved by a laser, but by an infrared-sensitive energy absorption fluid, a so-called high absorbing fluid. This binder is applied selectively via piezoelectric industrial print heads, and curing is performed with IR light. Special heat management over the entire powder bed ensures a consistently reproducible part quality even for fine details, flat areas, and large, homogeneous and smooth surfaces.

Highest precision for fine plastic parts

SAF is a highly industrial-grade technology that achieves homogeneous polyamide components even with extremely small, fine geometries. The maximum component size is 315 x 208 x 293 mm, and the layer thickness is 100 μm. For series production, SAF promises accuracy, repeatability, and process control, which are essential in industrial manufacturing today. The high production capacity results from the fact that printing and fusing take place in one operation, combined with a high assembly density. The technology strives to be competitive with injection molding and allows volumes in the hundreds to thousands of parts. Selective absorption fusion is ideal for e.g.:

- Connectors, hinges, cable holders

- Electronic housings, covers, and air ducts

- Precise end components from the commercial goods, automotive, consumer goods, and electronics industries

Send request >

Get in touch >

PolyJet

Process description

In the PolyJet process, also known as Fine Layer Technique (FLT), a liquid photopolymer is sprayed from an inkjet print head along the component contours onto the build platform and immediately cured using UV light. The build platform is then lowered and the next layer of the component is applied. Depending on the geometry of the component, PolyJet requires support structures to attach the component to the build platform and support overhangs. The special feature of this technology is that components can be produced in full color or texture, and several materials with different properties (e.g. solid and flexible) can be applied simultaneously in a single pass. Thus, components with very different properties and effects can be produced.

Realistic prototypes in full color

PolyJet can produce components with a layer thickness of 14 μm or 27 μm and a dimensional accuracy of +/- 0.1 % with very smooth (Ra ~6 μm), pore-free surfaces that can be pst-processed very well by grinding or polishing. Due to a minimum wall thickness of 0.5 mm, thin-walled and complex geometries are possible. PolyJet is ideal for e.g.:

- Design prototypes

- Artworks

- Presentation and exhibition models

- Absolutely photorealistic reproductions of originals thanks to CAPPS.IT, an additional service of FIT that guarantees color fastness

Send request >

Get in touch >

Fused deposition modeling (FDM)

Process description

FDM may not be the first but the best-known 3D printing technology. It was developed in the late 1980s and has evolved to be a very mature and stable technology. The technology is similar to that of a hot glue gun. A wire-shaped, thermoplastic filament is heated to the melting point in an extruder and deposited in liquid form onto a build platform along the contours of the component. In the process, the material hardens quickly by cooling, so that the next layer can be applied and the component can thus be built up layer by layer with a layer thickness of 0.15 mm to 0.3 mm (depending on the material selected). For cost and time reasons, solids are not produced solid but with filler structures. Depending on the part geometry, support structures are required, which have to be removed afterwards. Today, FDM is already used as an industrial technology in many industries for series production.

Robust components for high-performance applications

With FDM, dimensionally stable components with high stiffness can be produced cost-effectively over the long term. Unmachined components have a rough surface and reveal the individual construction stages, but many types of post-processing are possible, such as smoothing, painting, or coating. FDM allows a minimum wall thickness of 1 mm and has a lower accuracy compared to other 3D printing technologies. In return, however, a very wide range of processable materials up to composite materials and high-performance plastics is available for demanding applications. FDM is ideal for the production of e.g.:

- Functional components in aircraft

- Production tools in automotive plants

- Spare parts for railroads

Send request >

Get in touch >

This might also be interesting:

Metal coating

Clever: With our professional electroplating, you can give your components additional optical or functional properties at a low cost.

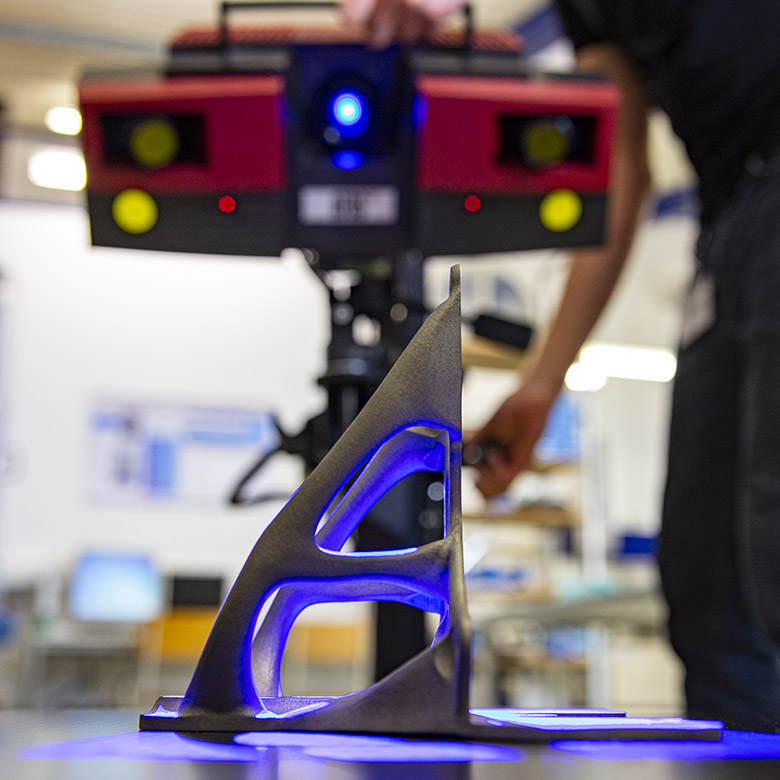

Learn more >Optical 3D scan

Do you want proof of the actual quality of your component? The optical 3D scan performs an exact shape and dimension analysis of the component in a non-contact and non-destructive manner.

Learn more >Innovation guide

Your indispensable compendium on all aspects of 3D printing. Here you will find everything about the various 3D printing processes, finishing options, machine data, and application examples from numerous industries.

Free download >